Knowledge

Craftsmanship develops through knowledge and experience

Specialist knowledge & technical guides

Show allWoodworking guide - Your introduction to woodworking & projects

Woodworking is a craft full of possibilities. Whether you are just setting up your first own workbench or have already completed a number of projects: We would like to share our experience, tips and practical instructions with you. at your fingertips. So you can realize your ideas safely and with pleasure.

The focus is initially on the basics. How do you choose the right wood? Which tools and machines are suitable for your workshop? And how do you use them precisely and safely? We will show you step by step how to saw, mill, sand or even make classic wood joints (such as dovetail joints). (such as dovetail joints) cleanly. If you like, you can benefit directly from our illustrated instructions, which clearly explain each stage of the work.

Are you looking for ideas for your first project? Or do you want to take your skills to the next level? We are happy to share inspiration for everything from small decorative pieces and shelves to complex furniture or sophisticated connections. We know the typical challenges from our own workshop experience and would like to show you that every hurdle can be overcome with the right knowledge. Your craft takes center stage - we accompany you as your experienced partner.

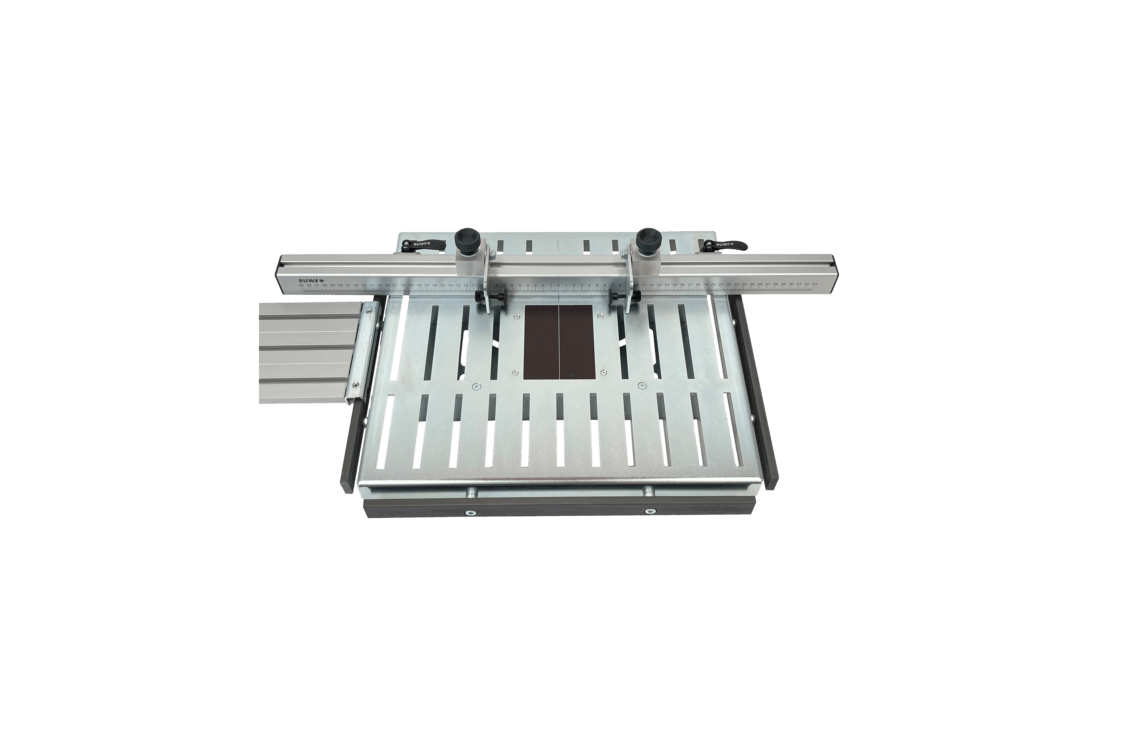

At RUWI, we want you to have a good feeling right from the start. That's why you'll not only find ideas here, but also in-depth knowledge about materials, tool selection and various techniques. We talk openly about the strengths and weaknesses of different methods and take you from rough cutting to a finely sanded surface. This allows you to achieve better results step by step - without unnecessary risk.

By the way, you can also find our tools at our partners: Sautershop, B+G Maschinenprofi, Ballas, Kirchner, Miller and Schachermayer.

We hope you enjoy browsing, trying out and creating. If you have any questions or need further tips, please get in touch. Start your next wood project whenever you want - we are here to support you with our knowledge and experience.