Profile milling with router and milling table - How to mill perfect profiles

Profile milling makes it possible to give workpieces a shape or contour on the edge or surface. Profile milling plays a central role in woodworking. It is therefore important to know what you need for this and how it is carried out. In this guide, we dive into the variety of machines and tools that are essential for profile routing with a router table.

Table of contents

- The most important facts at a glance

- Definition: What is profile milling?

- Procedure: Step-by-step instructions

- Tips for improving the milling result

- What machines are available for profile milling?

- What tools are available for profile milling?

- Which materials are suitable besides wood?

- FAQ

The most important facts at a glance

- Selection: Determine the right machine and suitable tool

- Safety: Correct handling and protective measures

- Optimization: uniform feed, correct speed, sharp tool

Definition: What is profile milling?

Profile milling is a milling process in which the contour (the profile) of the milling cutter is transferred to the workpiece. This is done for visual, haptic or design reasons.

Profile milling for visual / haptic reasons

- Wooden toys - edges are rounded to reduce the risk of injury

- Handrails / banisters - a good "gripping" or ergonomic profile

- Decorative milled profiles give the workpiece an individual look

Profile milling for design reasons

- Tongue and groove profile for floor coverings

- Gluing cutter to enlarge the gluing surface

- Counter profile for a framed door

- T-slot profile for fully extendable wooden drawers

Procedure: Step-by-step instructions for profile milling

Step 1: Choose the right machine

Manual router: You guide the routing tool over the workpiece. This offers a lot of flexibility.

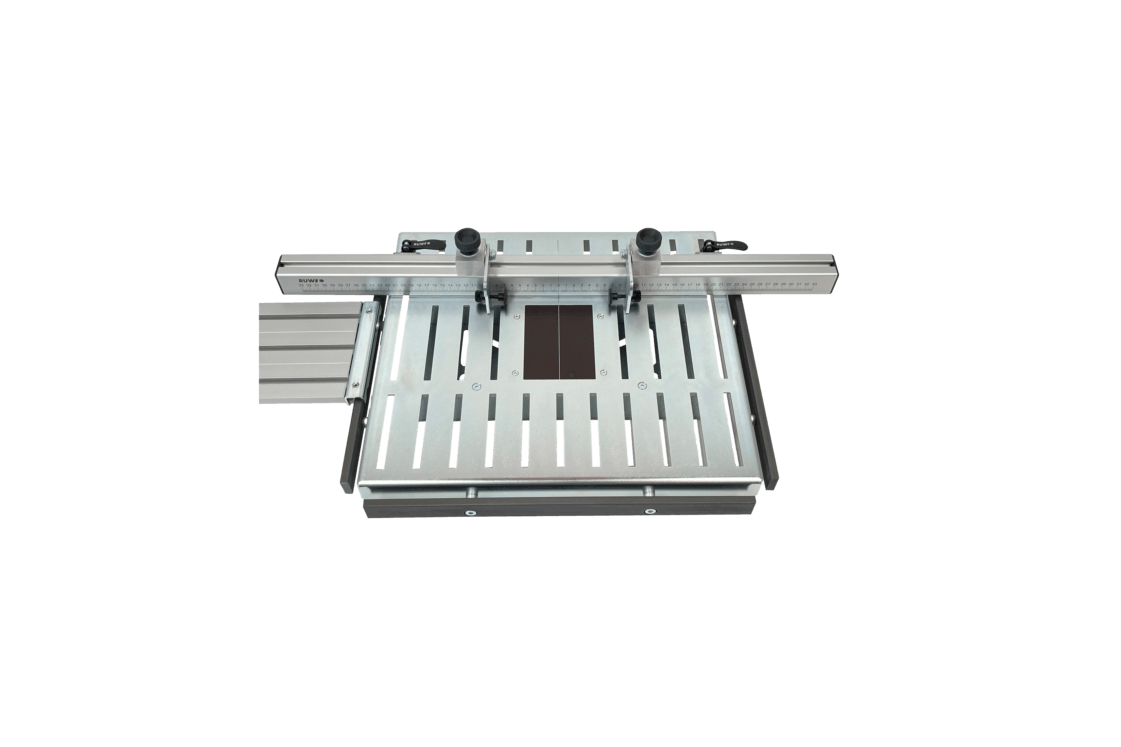

Router table: A stationary platform with a built-in milling motor. You move the workpiece over the stationary machine. This means high stability, a clear view of the tool and therefore precise results. A table extension can be useful for large parts.

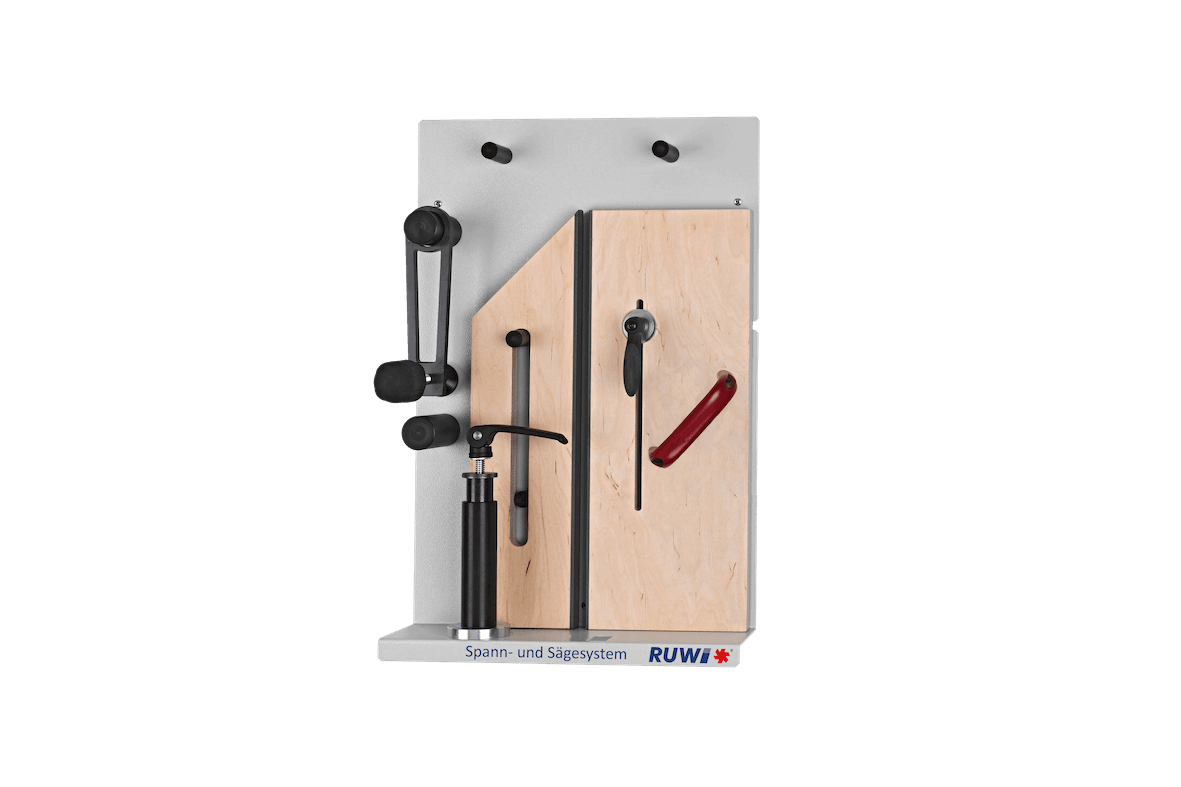

Discover now in the online store: Are you looking for a high-quality milling table? In the RUWI online store you will find various models to suit your needs.

Step 2: Tool selection and machine set-up

Choose the right router tool for your project. Pay attention to the collet size, tool diameter and the maximum permissible speed. A milling cutter with thrust ball bearings is suitable for curved parts. For linear routing or if you want to mill the profile into the surface, you can work on the router table with a fence or use a manual router with a guide rail.

Mount the tool securely up to the marking in the collet chuck. Make sure that the milling depth, speed and direction of rotation are correct before you start.

Milling tool selection - The right milling cutter for milling grooves

Important: Always follow the manufacturer's instructions for your machines and tools!

Step 3: Occupational safety

Workpiece fastening: An unsecured workpiece can catch and cause injury. Clamp your workpiece securely. Hearing protection: Protect your hearing from the noise. Eye protection: Wear safety goggles to protect against chips and dust. Dust mask: Prevent inhalation of wood dust. Clothing & jewelry: Avoid loose clothing, no jewelry.

More information: Berufsgenossenschaft Holz und Metall "Working with the hand router".

Step 4: Milling

Secure the workpiece firmly and ideally connect a dust extractor to the machine. Hold the router with both hands. Whether by hand or on the router table: If possible, mill in the opposite direction to achieve the best result and avoid injuries. An even feed rate ensures a clean routing pattern.

Note: If the speed of the motor drops, you should first remove fewer chips. Only a few milling motors have control electronics that compensate for speed fluctuations.

Step 5: Check and readjust

It is best to carry out a test milling to check settings such as milling depth and speed. Readjust if necessary.

Step 6: Maintenance and care of the milling tool

Clean the tool after the work process. Blunt milling cutters should be sharpened or replaced in order to achieve perfect results in the long term.

Tips for improving the milling result

- Optimize the speed: Depending on the type of wood and cutter diameter, a different speed may be necessary. Hard woods often tolerate a lower speed, soft woods may need more. Too high a speed with too low a feed rate can cause burn marks.

- Observe the maximum speed: The maximum speed specified on the milling cutter must never be exceeded.

- Test run: Use a scrap piece to test whether the milling depth and speed are correct.

- Sharp tools: A blunt milling cutter can cause tears and burn marks. Keep your router bits sharp or replace them in good time.

What machines are available for profile milling?

Depending on the material, the size of the workpiece and whether it is a one-off or series production, different machines come into question:

- Hand router: A mobile small machine, very versatile (DIY, woodworking, crafts).

- Milling table: Flexible and precise with short set-up times (ambitious woodworkers, trade / industry).

- Stationary bench router: Powerful edge profiling with manual or mechanical feed (ambitious woodworkers / craftsmen).

- CNC machine: Flexible profile milling with diamond profile cutters, on edges or surfaces (trade / industry).

What tools are available for profile milling?

- Rounding cutters in various sizes and radii

- Chamfer cutters in various designs

- Counter profile milling tools (set of two matching tools)

- Milling tools for tongue and groove

- Gluing cutter / Tine cutter

- Carnis cutter

- Quarter round cutter

- Chamfer cutter

Tip: Profile cutter sets are often cheaper than individually purchased profile milling tools. Compare offers from different manufacturers.

Which materials are suitable besides wood?

Although routers and profile milling tools were primarily developed for wood, plastics and certain easily machinable metals can also be processed. It is important to choose the right profile cutter and a suitable speed.

FAQ

What exactly is profile milling?

Profile milling involves using special profile cutters to mill a specific shape or contour into a piece of wood, for example a rounding, a chamfer or a more complex profile.

How do I choose the right profile cutter for my project?

This depends on your desired look, feel or function. Make sure that the milling cutter fits your machine and is suitable for the material to be processed.

What is the difference between a router and a router table?

A router is a portable machine that you guide over the workpiece - perfect for flexible applications or mobile construction site work. A router table, on the other hand, is stationary: The router motor is built in and you guide the workpiece over the stationary tool. This often allows you to achieve greater precision and safety.

How often should I sharpen my profile cutter?

This depends on your intensity of use and the material being processed. If you notice wear or a decline in cutting quality, it is time to sharpen or replace. Routers with reversible blades can be useful for heavy-duty use.

What do synchronization and counter-rotation mean when milling?

With climb milling, the milling cutter and workpiece move in the same direction; with up-cut milling, they move in opposite directions. Up-cut milling usually delivers cleaner results and is safer because the tool is not "pulled into" the workpiece.