Milling wood

When routing in wood, machines such as a router or router table use a rotating tool to precisely remove material to create the desired shape, contour or groove. This processing technique offers you many design options for a wide variety of wood projects. Use RUWI's valuable tips and advice to achieve the best results and take your routing projects to the next level.

Our comprehensive guide "Milling wood" provides you with precise step-by-step instructions and covers all the important sub-topics that you should consider when processing wood with a router or router table. Learn how to choose the right wood, find the right router tool and which machine is best suited to successfully complete your projects. Immerse yourself in the world of wood milling and discover the many possibilities offered by routers and router tables.

Table of contents

- What to look out for

- Choice of wood

- Choice of milling tool

- Choice of milling machine

- Materials in general

- Work preparation

- Step-by-step instructions

- Tips and tricks

What do I need to pay attention to before milling?

Before you start milling wooden parts, you should note the following points:

- Choose the right wood and the right tools.

- Consider whether a router is sufficient or whether specialized machines are better for your project.

- Make sure you select the machine that matches the desired processing.

- Clamp the workpiece securely and wear appropriate protective equipment.

- Set up your workplace safely and tidily.

Choosing the right wood

As a rule, you first select your wood based on the look and the planned function of the workpiece. However, different types of wood have different properties that make milling easier or more difficult and influence the end result.

Hard wood

Hardwoods such as beech, oak, maple, ash, cherry and walnut are popular for furniture making. However, you should work with a sharp cutter and an appropriate cutting speed, as hardwood puts more strain on the machine. Clamp the workpiece particularly carefully and remember to wear a dust mask, as hardwoods are often very dusty and can be harmful to your health.

Soft wood

Softwoods such as pine, spruce, fir or larch are easier to work with, but are sensitive to pressure when clamping. An extra pad or rubberized support prevents pressure marks. As softwood is less dense, rough milling edges or fibers can occur if the speed is too low. A higher speed and a sharp milling cutter usually ensure a clean result.

Wood-based materials

MDF, multiplex, and chipboard are often less expensive than solid wood and have consistent properties. However, they can be very dense, which makes it important to use suitable carbide cutters. In addition, wood-based materials often produce a lot of fine dust, so good extraction is essential. Adjust the cutting speed to avoid overheating or rapid tool wear.

RUWI recommendation: Solid woods such as beech or maple are suitable for the manufacture of children's toys, thanks to their robustness and low risk of splintering. Ultimately, however, the choice of wood type always depends on your specific requirements.

Choosing the right milling tool

The right choice of milling tool is crucial for the quality of the milling result and the service life of the tool and machine. Pay attention to the cutter type, diameter and material so that it is optimally suited to your project and your wood.

Types of milling cutters and their areas of application

- Grooving cutter: For grooves in different widths, often used in furniture and cabinet construction.

- Flush milling cutter: To remove protruding material flush (e.g. on templates).

- Chamfering cutters: Chamfering or "breaking" of edges, in various angles and sizes.

- Rounding cutter: For rounding edges or decorative profiles, in different radii.

- Disc grooving cutter: For tongue-and-groove joints, edge grooves, Lamello etc.

- Profile cutters: Decorative profiles, often for furniture fronts and decorative elements.

- CNC milling cutter: Specially designed for CNC machines, precise and repeatable results.

Conclusion: Find out about the different types of milling cutter and their typical applications so that you can choose the right milling cutter for your project.

Materials of milling cutters

- HSS (High Speed Steel): Relatively inexpensive and more break-resistant, shorter tool life.

- HM (carbide / tungsten carbide): Longer tool life and higher cutting speed, but more brittle and more expensive.

- Diamond-tipped: Very high precision and long service life, but very expensive and more suitable for special applications (e.g. CNC).

Conclusion: Carbide router bits are an excellent choice for most wood projects as they are precise, durable and versatile.

Choosing the right milling machine

CNC milling cutter

Computer-controlled machines for extremely precise and reproducible results. Ideal for complex shapes or series production. Spiral cutters, slot cutters and other tools can be used on CNC machines.

Bench milling machine

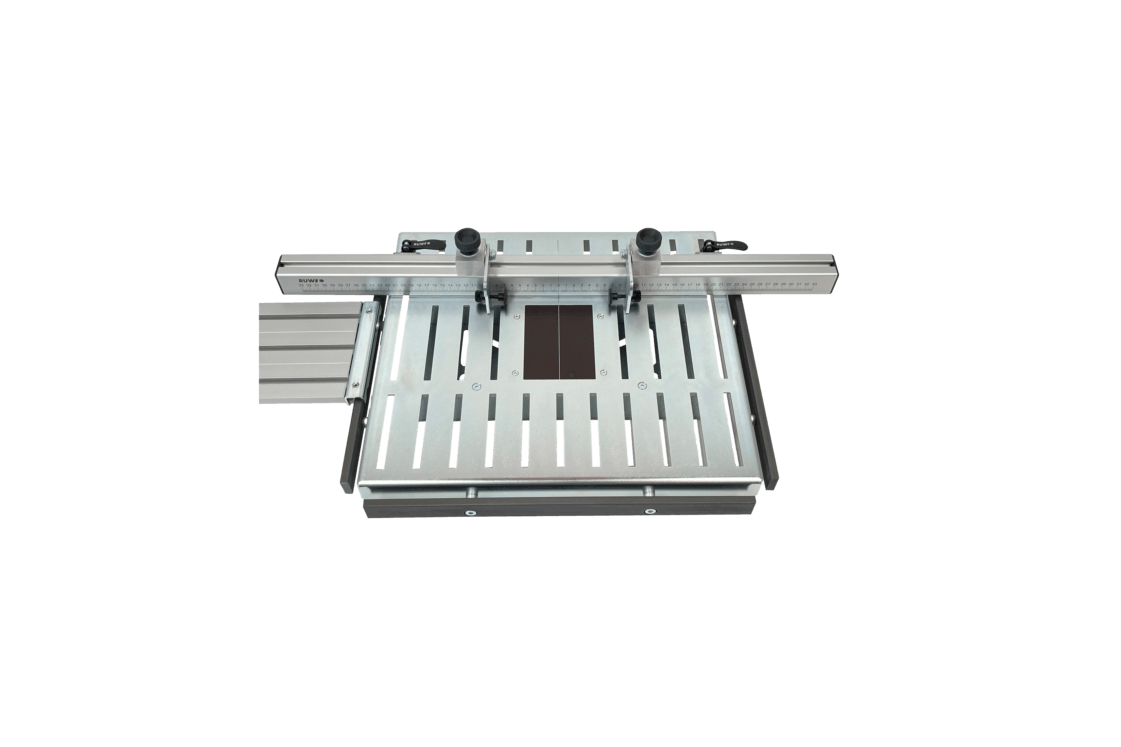

With a vertically positioned tool shaft, various processing operations can be carried out on the router table: Chamfering edges, rounding, tongue-and-groove joints, etc. Some table routers have mechanical feed devices.

Router

A hand-held router is mobile and versatile. Perfect for edge processing, small projects or use on the construction site. Ideal if you want to stay flexible.

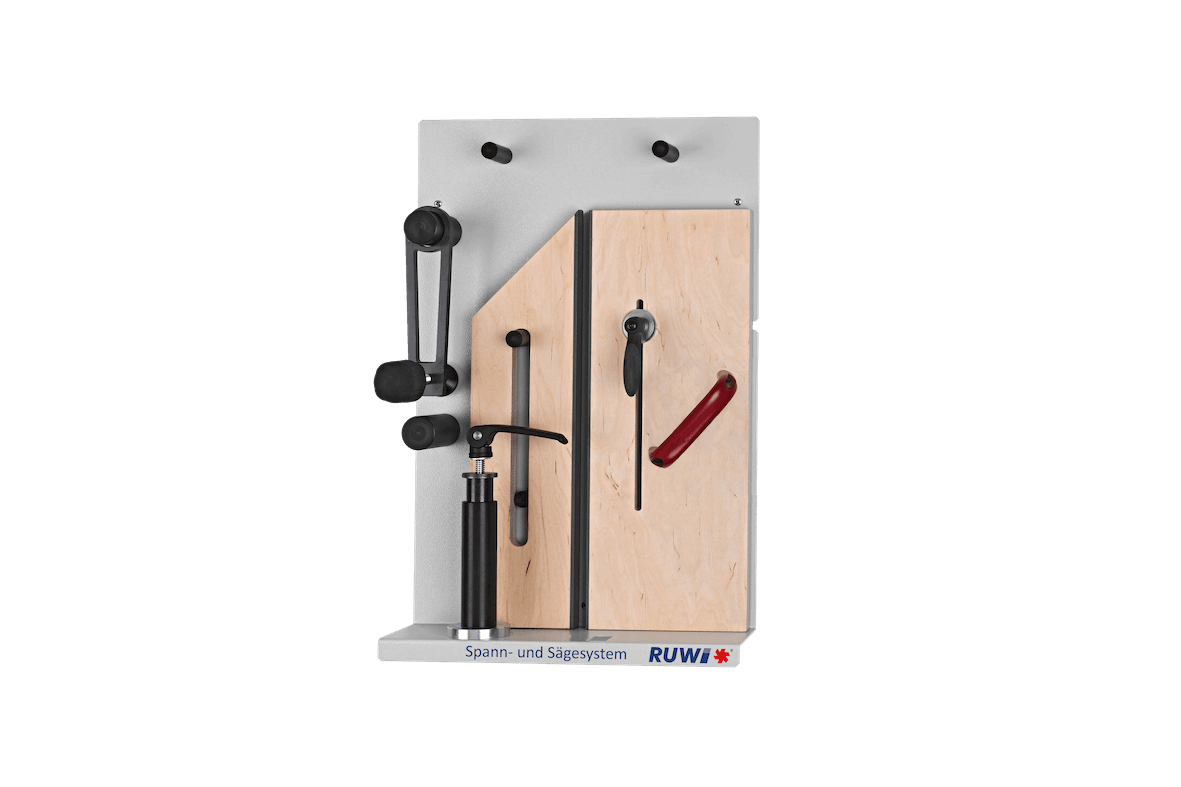

Underfloor milling machine / milling table

Here, the tool protrudes through the tabletop from below. With a stop and other devices, you can safely perform various milling operations (grooving, edge beveling, copy milling, etc.). Professional models (e.g., RUWI) feature effective dust extraction systems.

Chain cutter

Chain cutters or chain mortisers are primarily used in the carpentry and joinery sector for mortising tenons, i.e. elongated recesses. A rotating chain with cutting teeth ensures fast, precise processing of traditional wood joints.

Conclusion: Both the router and router table are ideal tools for many wood milling jobs. The router is flexible and portable, while the router table offers more stability and control.

Materials in general

You need certain materials and tools to achieve optimum results when milling wood:

- Wood / wood-based material: Choose a suitable type of wood for your desired look and function.

- Milling tools: Make sure the cutting edges are sharp and intact, worn milling cutters lead to poor results.

- Clamping devices: Secure the workpiece with screw clamps, clamping claws or other holders.

- Protective clothing: Use safety goggles, hearing protection and a dust mask to minimize injuries and health risks.

- Extraction: Effective dust extraction is essential to remove dust and chips and work cleanly.

Work preparation

Prepare workpiece

Plane or sand your board before milling so that subsequent sanding does not distort the milling profile. Markings are also easier to recognize on a smooth surface.

Choose the right milling tools

Check your router bits for sharpness and cleanliness. If they are worn, this will result in unclean cuts or even damage to the wood and machine. Insert the router bit into the collet up to the marking.

Settings on the router table

Pay attention to the speed, milling depth, feed direction and feed rate. A look at the operating instructions for your machine and tool will help you to find the correct values.

Important: The maximum speed specified on the milling cutter must never be exceeded!

Safety precautions

Always wear protective clothing, such as safety goggles, ear protection and a dust mask. Do not wear loose clothing or jewelry to avoid getting caught in the machine. A properly prepared workplace enables safe and precise work.

Step-by-step instructions

In our articles, you will find detailed guides for specific milling tasks such as milling grooves, rounding edges or producing profiles. Step by step, you will find out which tool you should choose and what you need to pay attention to.

Tips and tricks

Producing several identical parts with the router

Create a template from a sturdy material (e.g., plywood) and attach it to the workpiece. A flush cutter will precisely copy the template contour onto the blank. Or use a stop ruler and folding stops (e.g., on the RUWI router table) for repeatable positioning.

Care and maintenance of the router

Keep the router clean after each use, especially the ventilation slots and moving parts. Regularly check the condition of the router bits and sharpen or replace them if necessary. This will maintain performance and precision.

Select feed direction

Up-cut milling is generally recommended: The milling cutter rotates against the feed direction, which is safer. The surface quality can be better with climb milling, but it is more risky. A compromise: First cut roughly in up-cut, then minimally in climb milling.

Avoid wood dust

Use a powerful dust extractor and position the router and workpiece so that chips are directed toward the dust extractor. Ensure that the hoses and connections are leak-proof. Wear a dust mask to avoid inhaling fine wood dust. Professional machines, such as those from RUWI, often have a double dust extraction system (certified for wood dust extraction).