Face milling with the router

Step-by-step guide to surface routing wood

Whether you are a beginner or an experienced woodworker, every detail counts when surface routing wood. With a router and planer, you can level and smooth even large and challenging workpieces. In this guide, you'll find out what options are available without a jointer or planer and how you can create impressive projects. We'll show you which tools you need, how to proceed step by step and give you professional tips to ensure your results are of the highest standard.

Navigation

- How to face mill?

- Preparation

- Instructions

- Machine selection

- Tool selection

- Face milling devices

- FAQ

The most important facts at a glance

- Tool selection is crucial: Choose the right routing tool and a compatible router, complemented by effective dust extraction.

- Preparation pays off: Thoroughly prepare the workpiece, face milling device and safety precautions.

- Observe the technique: Pay attention to the milling direction and speed to minimize tears and increase the surface quality.

- Do not forget the finishing: Check the surface, sand and protect if necessary (e.g. oil, wax, varnish).

How can I plane with the router?

In face milling, the upper surface of a wooden workpiece is processed with a router and a special face milling tool to make it smooth and even. This is an alternative to working with a jointer or planer, especially for larger workpieces such as tree slices, epoxy resin tables or solid wood panels.

Preparation: What do I need for face milling?

In order for face milling to be successful, you should have the necessary material and tools to hand as well as some preparation time. The following list will give you some orientation:

Material list

- Workpiece (e.g. solid wood cutting board, tree slice, epoxy resin table ...)

- Vacuum cleaner / suction

- Dust mask / safety goggles

- Stable work table or workbench

Tools

- Clamping claws / fixing aids

- Face milling cutter (corresponding diameter)

- Face milling device

- Powerful hand-held router or pole router

Instructions: Face milling with the router

Here we show you step by step how you can quickly and easily plane uneven solid wood workpieces. You can achieve precise results with a router, a suitable router bit and a surface routing device.

Step 1: Tool selection

Choose a router and a routing tool that suits your project and material. Commonly used routers have 2 or 3 cutting edges and a diameter between 30 mm and 40 mm. There are also larger ones (up to 50 mm), but these require very powerful routers. A professional routing device that we recommend is the SlabMatrix from Sautershop.

Discover now in the online store: Are you looking for a high-quality milling table? In the RUWI online store , you'll find the right model for your needs.

Step 2: Prepare the machine and tool

Check the router and milling cutter for damage or wear. Insert the face milling cutter into the collet chuck up to at least the marking and tighten it. Pay attention to the preset speed and ensure that it never exceeds the maximum speed of the router. Then attach the machine to your face milling device, if provided.

Note: Caution - sharp tool edges! Wear gloves when fitting if necessary.

Step 3: Preparing the face milling device

Make sure that your router jig is mounted stably on the work surface. Check the height and alignment so that the router maintains the desired routing depth as it glides over the workpiece. Remove dust and dirt from the guides. If your jig is adjustable, adjust it to the size of the workpiece. A correctly adjusted jig prevents vibrations and ensures consistent results.

Step 4: Prepare the workpiece

Use a stable work table and a non-slip mat if necessary. Align the workpiece and support it if it wobbles. Clamp it firmly using clamps, clamping claws or eccentric clamps. With old wood, check for nails, screws or other foreign objects to avoid damage and safety risks.

Step 5: Milling the wood flat

Start at the highest point of your workpiece. Move the router in linear paths at an even speed. If possible, mill in the opposite direction. If a part has already been routed flat, you can lower the router bit by 2-3 mm and continue until everything is flat. Do not remove too much material in one pass so that the machine is not overloaded.

Tip: You can find out more about climb milling and up-cut milling in the encyclopaedia article on milling processes.

Note: A lot of wood dust is usually produced when face milling. Use a dust extractor and wear a dust mask.

Step 6: Finishing the wood

Check the surface for milling grooves and any irregularities. Then sand with grit 100-150 and then up to 220 or finer. Remove the sanding dust thoroughly before treating the surface with oil, wax, varnish or glaze. This gives the workpiece the necessary protection and a beautiful appearance.

Machine selection

Choosing the right machine is a decisive factor for precise face milling results. Common options:

- Hand router: Suitable for a wide range of jobs. Models with variable speed are particularly versatile. For many woodworkers, they are the "Swiss army knife" of routers.

- Rod milling machines: Often particularly robust and powerful, ideal for large wooden panels or hardwoods. The height is usually only adjusted via the face milling device itself.

Tool selection

- 2 or more cutting edges: Fewer cutting edges are ideal for moderate material removal, more cutting edges for large areas and fast work.

- Fixed-tipped milling cutters vs. reversible kn ives: Fixed-tipped carbide cutting edges are often cheaper, but must be given for sharpening. Reversible milling cutters allow easy turning or replacement of worn cutting edges.

- Shank diameter: Common sizes are 8 mm, 10 mm, and 12 mm. Make sure they're compatible with your router.

- Tool diameter: Face milling cutters range between 25 mm and 50 mm. The larger the diameter, the more power and stability the milling cutter needs.

Always choose a milling tool that matches the scope of the project and the specifications of your machine.

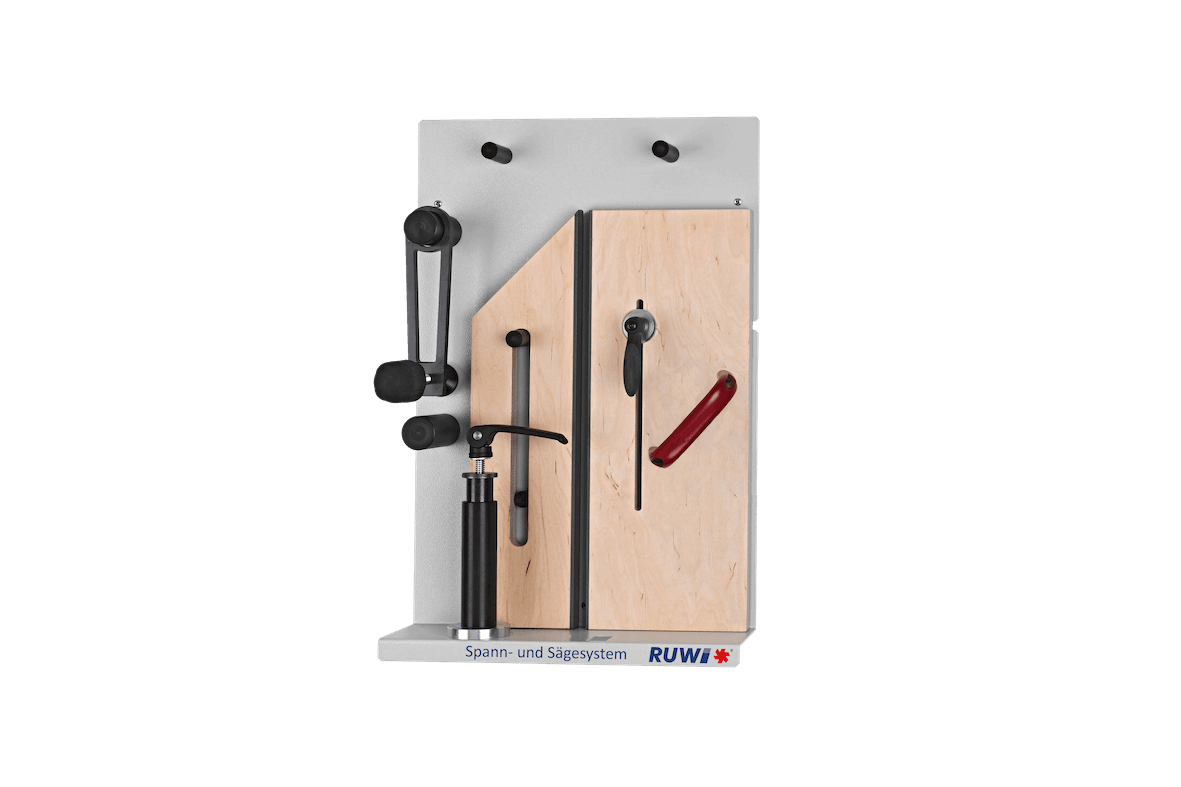

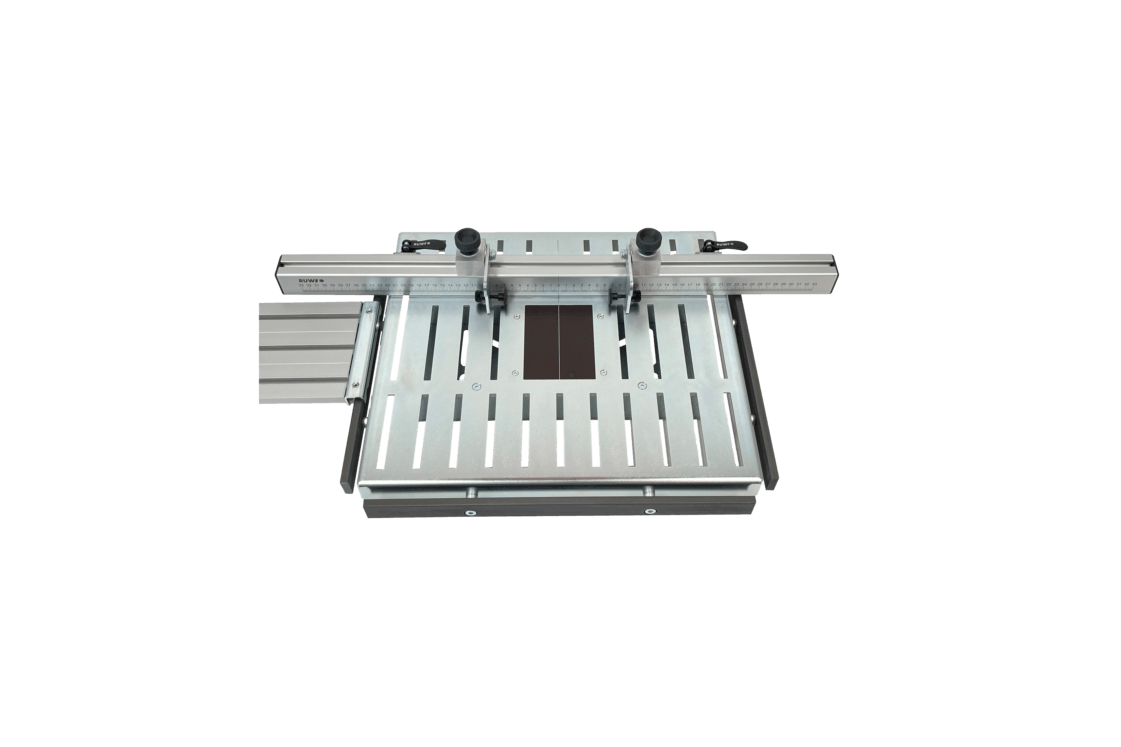

Face milling devices

Face milling devices are the key to precise and even face milling. Various versions are available:

- Simple face milling jigs: Ideal for DIY enthusiasts or small projects. Provide a basic guide for the router, but are usually only suitable for smaller workpieces.

- Professional face milling tables: For demanding or commercial applications. Robust construction, integrated suction, precise height adjustment and adjustable stops if required. Suitable for larger workpieces and very precise face milling.

The decision between a simple DIY solution and a professional face milling table depends on your requirements, budget and desired precision.

Find out more in the woodworking lexicon: Face milling

FAQ

What is face milling?

Face milling is a woodworking technique in which the surface of pieces of wood is milled flat and smooth using a router, a suitable face milling cutter and a face milling device. This makes it possible to remove unevenness and produce precise thicknesses.

Which router is suitable for face milling?

A router that is suitable for face milling should be powerful enough to drive larger face milling cutters and have a precise depth setting. A variable speed is helpful in order to be able to react to different materials. Ergonomics and good dust extraction improve working comfort.

How do I avoid tear-outs when face milling?

Preferably mill in the longitudinal direction of the wood fibers, use a sharp milling cutter and adjust the speed accordingly. If necessary, use a splinter block to support the exit edge. This will keep unsightly tears to a minimum.

Do I need a special face milling device?

Yes, a face milling device is necessary to precisely control the milling depth and remove the workpiece evenly. It ensures reliable results and prevents unwanted vibrations or skewing.

Which face milling cutter is the best for my project?

This depends on the material, the desired surface quality and the frequency of use. Routers with reversible blades are easier to replace when worn. Be sure to pay attention to the shank diameter, cutter diameter and the permissible speed of your router.