Milling roundings in wood - perfect rounding of wooden edges in 5 steps

It's so easy: Perfectly milled roundings with a router or router table

Rounding off edges is one of the most common processes in woodworking, which not only improves the appearance of furniture and workpieces, but also makes them safer and more pleasant to handle. Sharp edges are processed in such a way that they are less pointed and therefore less prone to injury.

This 5-step guide shows you how to professionally round wood edges with a router - from preparation to implementation. Whether you are a hobby craftsman, woodworker or a professional such as a carpenter or joiner, you will find the information you need here.

Table of contents

- Important facts at a glance

- Preparation

-

Milling rounding instructions

- Set radius size

- Setting the milling depth

- Clamping and protection device

- Milling rounding

- Post-processing

- Tips for improving the milling result

- Machines and tools for circular milling

- What other types of circular milling are there?

- FAQ

Important facts at a glance

Preparation: Decide which machine and which rounding cutter is best suited to your project.

Execution: Ensure that the milling depth, speed and milling direction are set correctly.

Post-processing: Allow sufficient time and the right know-how for the finish.

Preparation: What do I need to mill a rounding in wood?

Circular milling opens up many possibilities for you to change the look and feel of your workpiece. Our step-by-step guide will accompany you from preparation to implementation.

Router or router table: Both machines are suitable for rounding off edges. Which one you choose depends on your personal preference and the specific requirements of your project.

Milling tool: Selecting the right milling tool is crucial for milling a rounding on a wooden part. Use different milling heads in different sizes to achieve the desired rounding - from small edge breaks to large radii. There are also special tools such as the R2 double rounding and chamfering cutter, which allows you to process two edges at the same time.

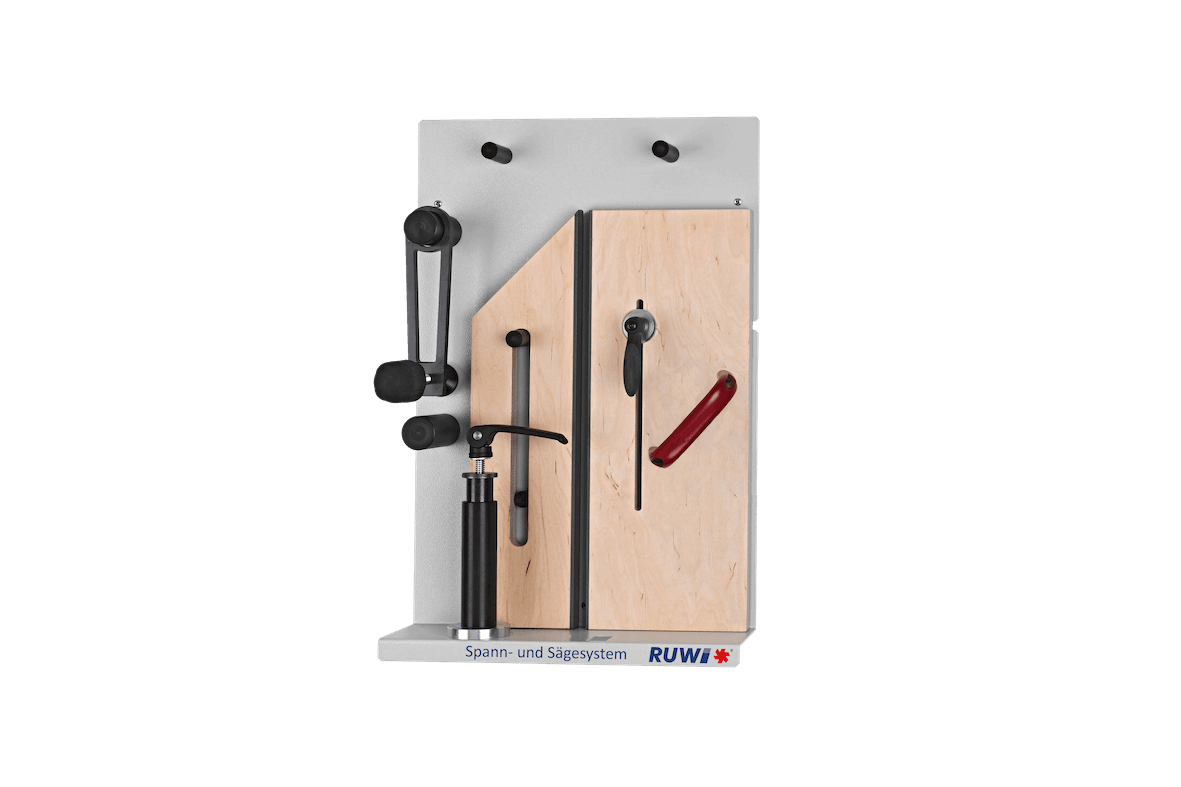

Clamping device: If you are using a manual router, clamping devices such as a Bessey 200 mm screw clamp with clamping bolts and clamping claws are essential for positioning your workpiece securely and precisely. An even safer method is to use a router table, as you always have the tool in view. A tool cover also allows you to safely round off even the smallest parts.

Protective equipment: Working with a router or router table requires the right protection. Therefore, always wear safety goggles and hearing protection. Depending on the material and tool, a dust mask may also be useful.

Make sure that all tools and materials are in perfect condition before you start routing. Thorough preparation not only ensures a better result, but also your safety during the work process.

Material list

- Tilt or non-slip base / work table

- Workpiece to be rounded

- Material for test milling

- Sandpaper

Tools

- (Hand) router or router table

- Radius milling cutter / quarter rounding cutter / rounding cutter

- Clamping tools

- Sandpaper / sanding block

- Extraction, PPE (personal protective equipment)

Milling rounding instructions

In this step-by-step guide, we will show you how to create perfect curves in your workpiece using a router or router table. From selecting the right radius size to checking and post-processing the routing result, we will guide you through the entire process and help you achieve optimum results.

Step 1: Determining and setting the desired radius size

You should choose the size of the rounding depending on the look and functionality. A minimum requirement is often a rounding cutter R2 as an edge break to soften sharp edges. For items such as children's toys, a larger radius (≥ R5) is recommended to make the toy more tactile and easier to grip. This also reduces the risk of injury and increases the lifespan as small parts are minimized from splintering.

Make sure that the machine is switched off and disconnected from the power supply while you are inserting the tool. When clamping, make sure that the rounding tool is seated in the collet up to the mark on the shank.

Step 2: Setting the milling depth

If you want to round off curved edges, we recommend using a rounding cutter with a stop ring. The stop ring traces the contour and guides the router bit cleanly along the curved edge. For straight workpiece edges, you can also use a router bit without a stop ring by guiding the workpiece along the fence of the router table or the rip fence of the hand router. In both cases, however, it is important to set the routing depth correctly.

The radius of the milling cutter should be flush with the machine table. If the cutter protrudes too far, a shoulder will form; if it protrudes too little, a small edge will form at the transition. You can adjust the cutter height using a digital setting gauge or on a test piece until the outermost edge of the cutter just touches the wood surface. A test routing will show you whether you have the right setting.

Tip:

Sometimes it can be attractive to deliberately set the rounding cutter slightly lower to achieve a special decorative edge look (the "German rod"). Try out different settings to find the look you want.

Step 3: Clamping and protection devices

To round the edges of the workpiece safely and precisely, you should clamp it well. Use screw clamps, quick clamps or clamping claws. To avoid pressure marks in the wood, place a support between the workpiece and the clamp. For heavy workpieces, it may be sufficient to place them on a support rail with an anti-slip coating. Then you can mill all around without a clamp getting in the way. However, make sure that the workpiece does not slip.

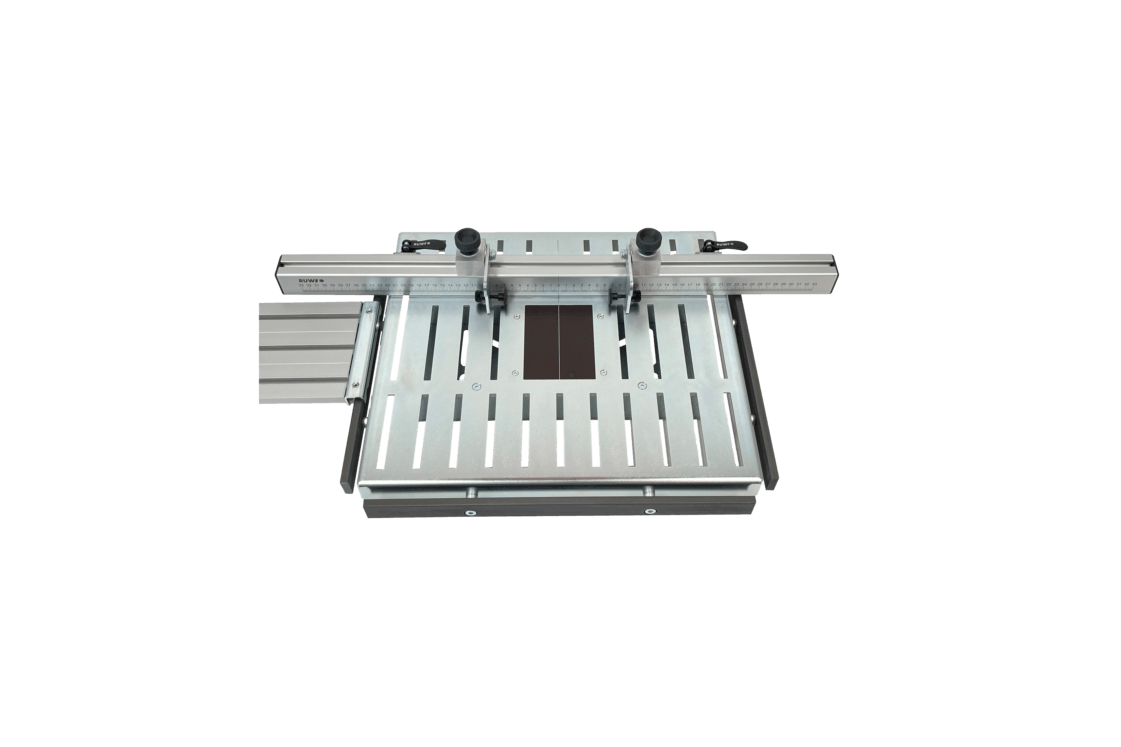

If the wood is rounded on the router table, you should use a tool cover. The RUWI router table allows you to safely round even tiny parts such as wooden jewelry. Plastic insert rings minimize the gap to the rounding cutter and maximize the contact surface.

Note: Remember the extraction system and always wear your PPE (hearing protection, dust mask, etc.) when working with machines and tools.

Step 4: Milling

As soon as you have carefully set the milling depth and attached the clamping and protective devices, you can start the actual milling process. First check that the correct speed is set and then switch on the machine. As a rule, you mill in up-cut mode, only rarely and with great care in down-cut mode. Find out about the differences between synchronized and counter-rotation in order to understand the advantages and disadvantages.

You can find more information on milling processes in our encyclopedia article on up-cut milling.

Guide the router tool along the edge with even pressure and speed. With a manual router, it is particularly important that the router does not tilt. The workpiece rests on a large surface on the router table so that you guide the workpiece (instead of the machine).

Tip:

With a suitable rounding cutter on the router table, you can even turn a square bar into a round bar with ease. The best way to do this is to watch a video on the subject of "Milling round bars".

Step 5: Checking and post-processing

Check the milled workpiece carefully for irregularities or unevenness. Make sure that the rounding is even and clean. If you see irregular indentations (planing strokes), the thrust ring may be dirty or the feed speed may have been too high. A slightly lower speed may help.

Smaller irregularities and the transition from the rounding to the surface can be carefully smoothed with 120-180 grit sandpaper. Wear a protective mask to protect yourself from wood dust.

After completing the milling work, you should clean the milling tool and inspect it for any damage. If necessary, have the tool sharpened.

Tips for improving the milling result

- Practice makes perfect: First mill a practice piece to get a feel for the machine before tackling your final project.

- Cutter quality: A high-quality cutter can make a big difference. Look for durable cutting edges for better results.

- Sufficient support surface: For larger workpieces, a table extension can help to increase the support surface.

- Prevent tipping: Expand the support surface of a handheld router by screwing a Plexiglas plate (approx. 25 x 25 cm) under the base. Or place material of the same thickness parallel to the edge to ensure the router rests securely.

- Several steps: For large curves, it is better to mill in 2-3 steps to minimize chip removal and achieve a cleaner result.

- Care and maintenance: Clean the milling cutter and milling machine after each use. Make sure they are sharp and read the operating instructions to ensure that everything runs smoothly.

Machines and tools for circular milling

Choosing the right woodworking machine depends on the type and size of the project as well as the desired profile size and precision:

- Hand-held routers: Good for smaller projects or if you want to work flexibly. Mobile use, e.g. on the construction site. This includes the edge router or rod router, especially for edge processing.

- Router tables: Ideal for larger projects or when you need repeatable precision. They are used by DIY enthusiasts as well as woodworkers and educational institutions. With profile solutions such as the RUWI router table, you can work quickly and safely.

- Stationary bench milling machines / CNC milling machines: For complex or serial milling work - especially in the professional sector.

- Sanding machines (e.g. belt sanders): Suitable for rounding edges, but require practice. Good for organic shapes.

- Hand planer: If you like it classic and are suitably practiced, you can also plane a rounding by hand.

What other types of circular milling are there?

In addition to the frequent "edge rounding", there are other types of round milling:

- Rounding a corner: You round the outer corners of a surface, e.g. a table top.

- Round milling instead of drilling: If you want to mill a hole in a workpiece, e.g. for a round sink recess in a kitchen worktop.

FAQ

Why does the rounding have brown spots / burn marks in some places?

This can be caused by too high a speed, too low a feed rate or a blunt milling cutter. Excessive friction leads to heat development, which can burn the wood. Therefore, make sure that the speed is adjusted, the feed rate is fast and the tools are sharp.

Why is the milled rounding profile uneven or rough?

If the thrust ring is dirty or the workpiece has not been clamped correctly, so-called planing strokes or unevenness can occur. Too high a feed speed also leads to chatter marks. Clean the thrust ring, adjust the speed and clamp the workpiece firmly. If the roughness is only slight, you can rework with fine sandpaper.

How can I make a round bar?

For a round bar, you need a square bar with a cross-section that matches the radius of your router bit. For example, a 16 mm diameter round bar requires an R8 quarter round bit and a 16×16 mm bar. For a 12.7 mm diameter bar, you need 25.4×25.4 mm (2×12.7 mm). This is easier to do on a router table (with a clamping device) than freehand with a handheld router.

What is the correct rounding radius for my workpiece?

This depends on your desired look and function. A small radius (e.g. R2) looks discreet, a larger radius (≥ R5) makes the edge more grippy. It is best to test what you like best on a sample piece.

How do I set the correct speed for my router table?

The maximum speed must never be exceeded (see information on the milling cutter). Soft woods can be milled at a lower speed, hard woods often require more power. Too high a speed leads to heat and burn marks, too low a speed leads to chipping. It is best to try out different settings on a scrap piece.