Up-cut milling

Up-cut milling is one of the most frequently used milling methods for removing material in woodworking. Different methods are used depending on the workpiece, material and position. Although climb milling is often preferred for various reasons, up-cut milling also has its place. The relationship between the feed direction and the direction of rotation of the milling head plays a decisive role here.

In this article, you will learn everything you need to know about up-cut milling: What exactly is up-cut milling? How does it differ from climb milling? We also explain the advantages and disadvantages as well as the range of applications of up-cut milling.

Table of contents

- Definition of

- Advantages

- Disadvantages

- What is the difference between climb milling and up-cut milling?

- When is up-cut milling preferable to climb milling?

- Which is better: climb milling or up-cut milling?

- When are up-cut milling machines used?

Definition: What is up-cut milling?

Milling is a machining process in which a rotating tool (the milling cutter) removes material. Up-cut milling is a sub-area of this process. The special feature: The cutting edges of the milling head rotate in the opposite direction to the direction in which the workpiece is fed.

Advantages of up-cut milling machines

Unlike climb milling, up-cut milling usually involves fewer risks. When you manually advance the router, you guide it against the material. This counter-rotation reduces the risk of getting your hand caught in the rotating tool. Counter-rotation milling is also recommended for older machines with a lot of play in the feed. Counter-rotation milling has proven its worth with wood, and there is also less wear on cast parts.

Disadvantages of up-cut milling machines

In contrast to climb milling, the results are often less clean. Higher pressure is applied during the milling process, which can lead to faster wear of the cutting edges. The milling machine also requires more power, which reduces efficiency.

What is the difference between climb milling and up-cut milling?

In climb milling, the milling cutters rotate in the same direction as the feed, so that the chip thickness is greatest at the beginning and decreases towards the exit. In up-cut milling, the milling cutter and feed rotate in opposite directions, so the chip thickness starts at zero and increases towards the exit. Chips (comma chips) form differently, which has an influence on heat, cutting pattern and wear.

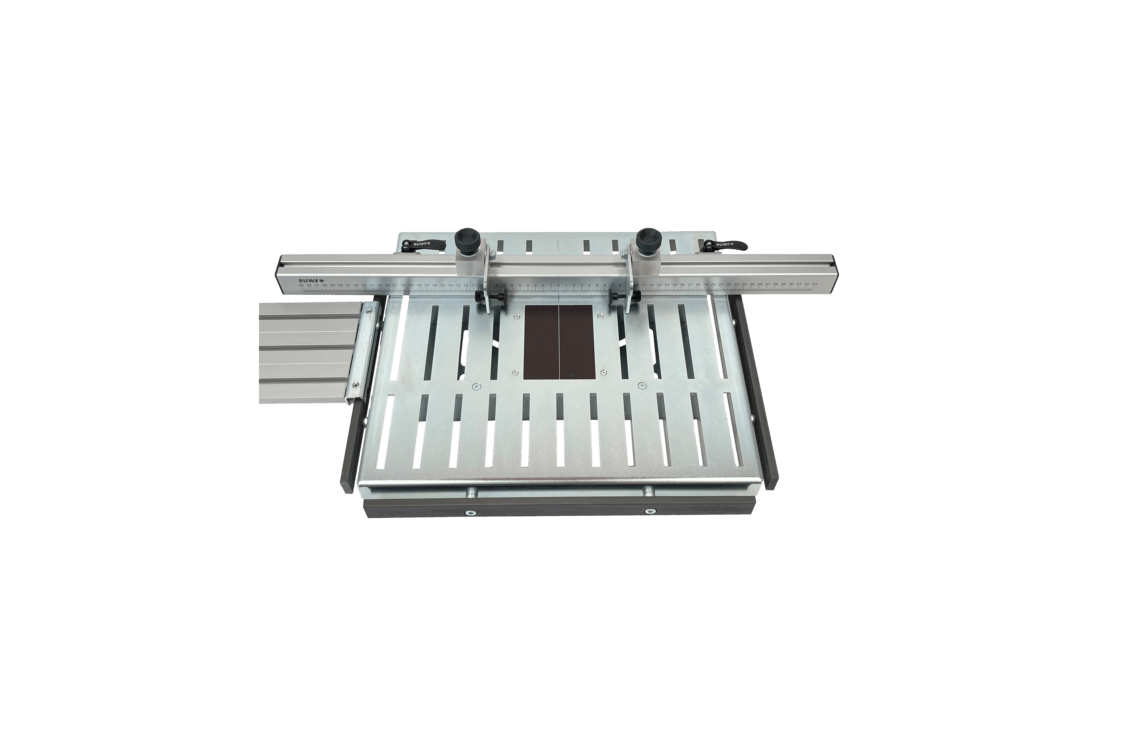

Tip: RUWI milling table for CNC milling with wood

A RUWI milling table offers you a semi-stationary system for precise milling work on a stable work table - with a high degree of flexibility at the same time. Learn more now

When is up-cut milling preferable to climb milling?

Up-cut milling is particularly suitable when the milling result does not have to be extremely clean - for example, for rough removal. You often mill away the majority of the material in up-cut mode and perform the fine cut in climb milling. With manual feed, climb milling is sometimes prohibited or heavily regulated by the trade associations. Even if the clamping situation is inadequate and you cannot safely absorb strong "tensile forces" (as with climb milling), it is better to choose up-cut milling.

Which is better: climb milling or up-cut milling?

Synchronized milling usually delivers cleaner results and avoids tear-outs. However, there are higher risks involved. Up-cut milling is generally less dangerous, but the milling pattern is rougher and the wear on the cutting edges can be greater. In many cases, it is advisable to pre-rough in up-cut mode and finish milling in climb milling mode.

When are up-cut milling machines used?

Up-cut milling is mainly used for workpieces made of wood or those with hard and abrasive edges. It is often recommended because the risk of danger is lower compared to climb milling. If you want the end result to be particularly smooth, you can run several infeeds or re-mill later in climb milling to minimize tear-outs.