The tried and tested RUWI lift tables with 20 mm clamping technology

RUWI lift tables - flexible, ergonomic and resilient

Our RUWI lifting tables are more than just height-adjustable workbenches. They combine a mobile assembly bench, clamping station and transport aid in one. Thanks to the infinitely variable hydraulics, they adapt to any work situation and ensure ergonomic working - without any back pain. This article provides you with a comprehensive overview of the models, differences and advantages, as well as tips for making a purchase decision.

- Overview & special features

- Technical data & comparison

- RUWI Basic lift table

- RUWI Classic lift table

- RUWI Premium lift table

- RUWI lift table base frame

- Functions & equipment

- Areas of application & target groups

- Advantages & possible disadvantages

- Purchasing advice & service

Overview & special features

All RUWI lift tables are based on a robust scissor design made of rectangular steel tubes. With our smooth-running hydraulic foot pump, you can adjust the working height continuously - perfect for lifting heavy workpieces to a back-friendly height. Four swivel castors (each lockable) guarantee easy relocation in your workshop. This allows you to move the table to wherever you need it and then lock it securely in place.

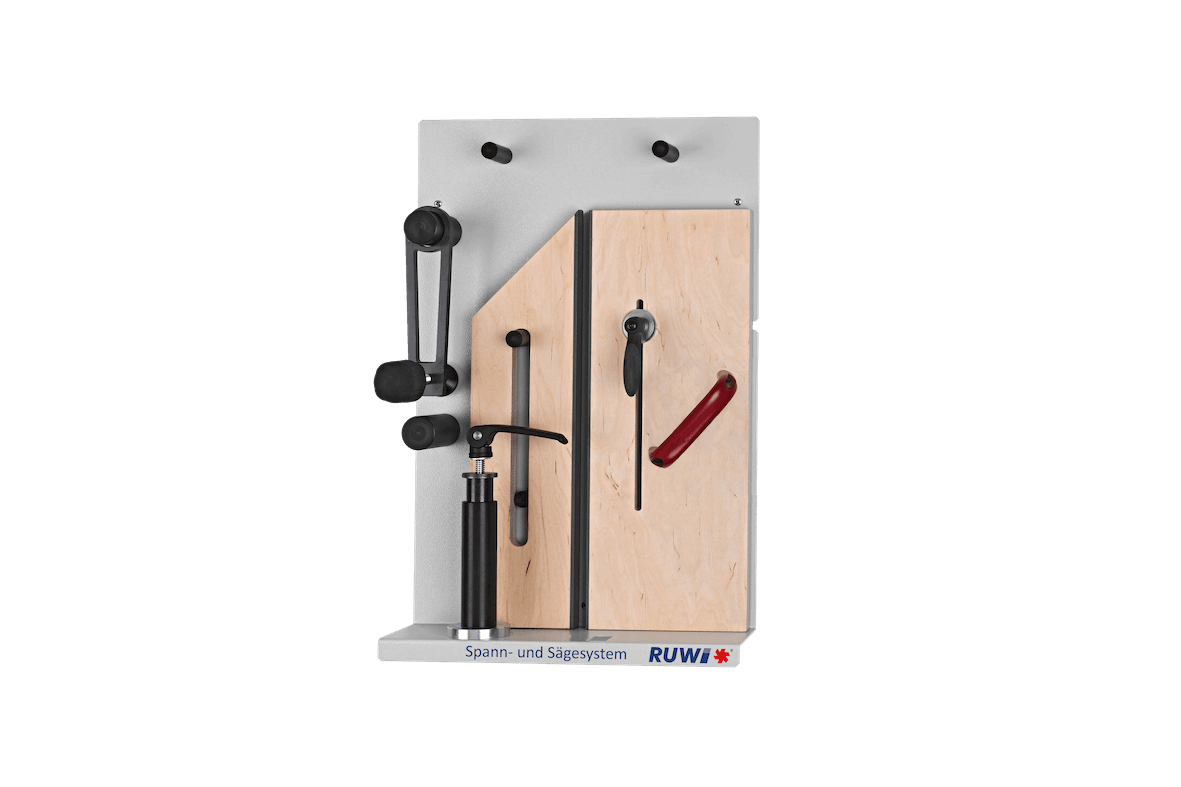

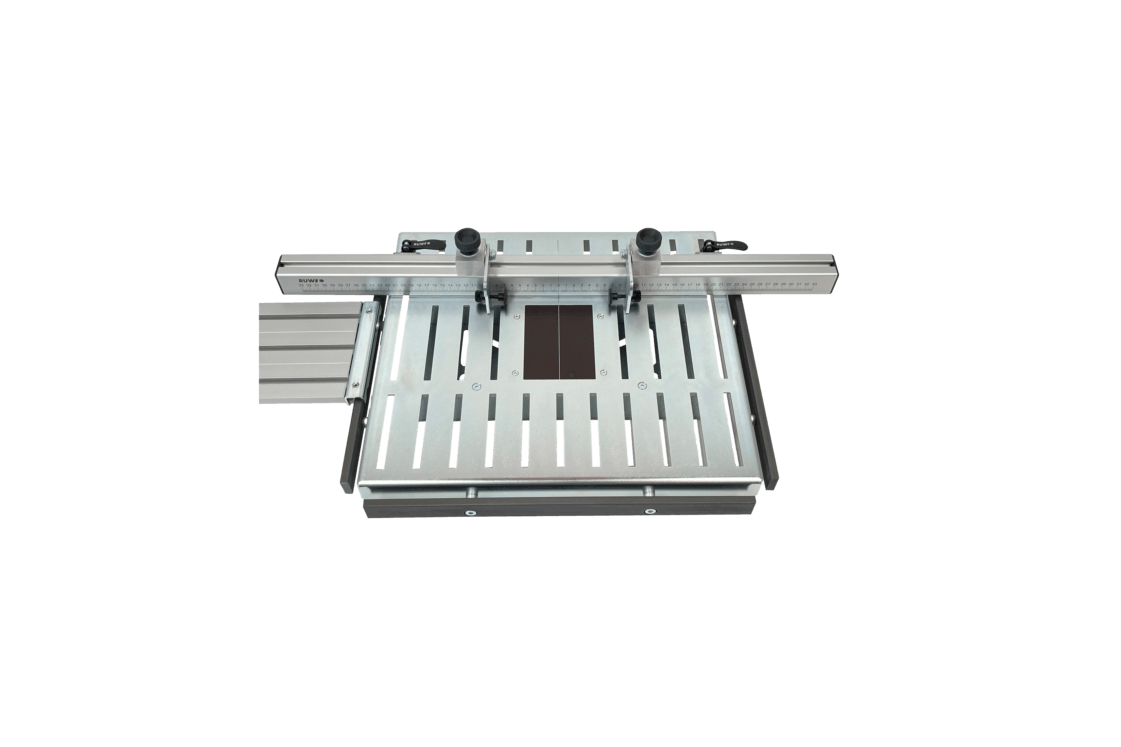

Our characteristic hole grid system (20 mm in a 96 mm grid) turns every RUWI lift table into a clamping station: you can flexibly position clamps, clamping bolts, stops or support rails. Each table also has an HPL-coated multiplex top - scratch-resistant, durable and easy to clean. With a load capacity of up to 300 kg, our models are suitable for all common tasks in trade, industry and ambitious hobby workshops.

Technical data & comparison

We offer three ready-made lift tables - Basic, Classic and Premium - as well as a base frame without a top that you can equip as you wish. In the table below you will find a direct comparison of the most important features.

| Model | Load capacity | Height adjustment | Platform | Extension |

|---|---|---|---|---|

| Basic | up to 300 kg | stepless (low-medium height), foot pump | Multiplex, approx. 1200×800 mm, approx. 96 drill holes (Ø 20 mm) | No pull-outs, reduced equipment |

| Classic | up to 300 kg | stepless (medium-high height), foot pump | Multiplex, approx. 1600×800 mm, approx. 128 drill holes | 2 extendable segments, drawer & storage space |

| Premium | up to 300 kg | stepless (medium-high height), foot pump | Multiplex, 1200×800 mm, swivels up to ~1600×1200 mm, approx. 192 drill holes | Second perforated plate can be opened, incl. clamping technology package |

| Underframe | up to 300 kg | stepless, foot pump, depending on plate | without table top, steel frame ~110×64 cm | Own design concept, freely configurable |

RUWI Basic lift table

Our Basic model is aimed at anyone who can do without extendable top sections or drawers and simply wants a solid, hydraulically adjustable base. Thanks to its compact footprint, it also fits into smaller workshops or serves as an additional module if you already have other tables.

Despite its rather purist design, the Basic offers the same high-quality scissor mechanism as the larger models. The perforated plate with HPL coating measures approximately 1200×800 mm and has approximately 96 holes (20 mm). This allows you to flexibly use clamping devices and safely machine workpieces weighing up to 300 kg at the desired height.

RUWI Classic lift table

If you are looking for more work surface, integrated storage space and an extendable top, the Classic is a real all-rounder. The base plate measures approx. 1600×800 mm, with two extendable segments at the front edge that can each be extended by around 30 cm. This gives you a significantly larger support surface - ideal for long workpieces or several smaller projects.

A drawer and open compartment directly beneath the worktop provide space for clamping accessories, tools, or support rails. With its medium to high working height and robust scissor-type design, the Classic can lift up to 300 kg and remains mobile at all times thanks to four swivel casters.

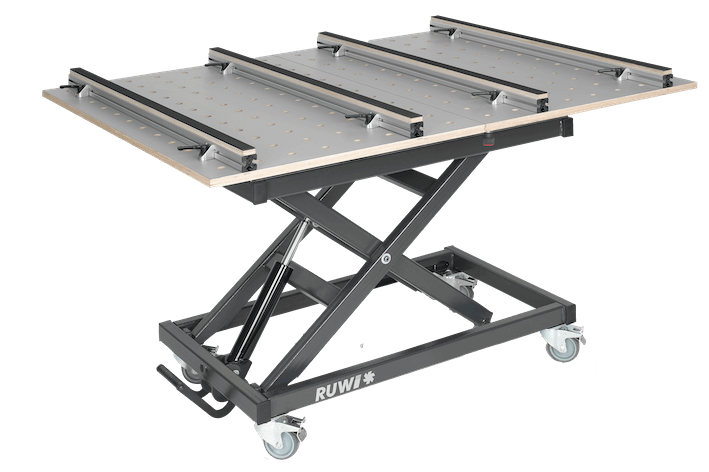

RUWI Premium lift table

Our premium model combines everything you need for maximum flexibility. In addition to the base plate (around 1200×800 mm), you can fold up a second perforated plate using a swivel mechanism and expand it to around 1600×1200 mm in a matter of seconds. This creates a huge, continuous work surface that can also safely support large or bulky components.

You also receive a clamping technology package with support rails and clamping brackets, plus a spacious drawer and other storage options. As with all RUWI lift tables, the hydraulic foot pump allows you to adjust the height continuously, while four lockable castors ensure stability. This saves you an enormous amount of time and offers real convenience, especially for complex or very large projects.

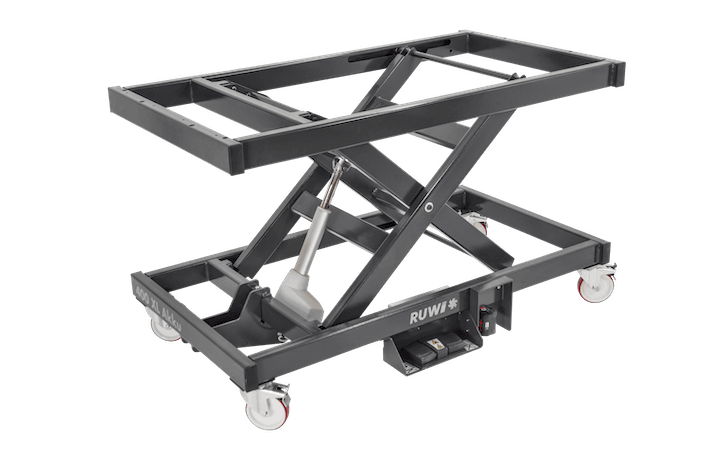

RUWI lift table base frame

If you already have your own ideas for the table top, our base frame is the perfect foundation. It provides you with the complete scissor mechanism with hydraulics and castors, but without the multiplex top. Instead, you can mount an individual top or a special construction - for example a metal frame, a different perforated grid top or even a machine mount.

The base frame gives you the same load capacity and height adjustment as our finished models. However, you remain completely free in the choice and design of your work surface. This is particularly exciting for companies with very specific requirements or for special solutions that a standard lift table does not cover.

Functions & equipment

- Hydraulic scissor mechanism: Stepless adjustment by foot pump, without effort, back-friendly and robust.

- 20 mm hole pattern: HPL-coated multiplex board on both sides with sufficient holes for clamping and fixing tasks.

- Mobile design: Four solid rubber castors, each with brakes, allow you to position the unit quickly and stand securely.

- Variety of versions: Basic, Classic, Premium or base frame - depending on space requirements, project scope and desired equipment.

- Durability: Welded steel profiles, careful production and reliable mechanics "Made in Germany".

Areas of application & target groups

RUWI lift tables are suitable for a wide variety of tasks - from occasional help-outs as mobile storage units to daily assembly, gluing and clamping centers in the workshop. Frequent application scenarios are

- Wood and furniture processing: carpentry, joinery, interior fittings

- Plastic processing: subsequent adjustments, grinding, chamfering

- Industry & trade: ergonomic assembly, flexible transport aid

- Training workshops & schools: back-friendly working, adaptable to different body sizes

- Hobby & professional workshops: if you if you work at a professional level and want real quality

Thanks to the hydraulic height adjustment, you can fix workpieces at the ideal working height and protect your back and joints. In larger companies, our tables help to save time, as you don't have to constantly change over several work tables. Mobile gluing or working in parallel at different stations are also major advantages.

Advantages & possible disadvantages

Advantages:

- Ergonomic adjustment: Adjustable height via hydraulics

- High stability: welded steel profiles, tilt-proof up to 300 kg

- Hole grid system: professional clamping without additional devices

- Mobility: can be quickly moved around your workshop, brakes on the castors

- Durability & quality: "Made in Germany", robust mechanism for continuous use

Possible disadvantages:

- Investment costs for high-quality hydraulics and solid construction

- Foot pump system instead of electrohydraulics, but rarely a problem in practice

Purchasing advice & service

We recommend that you clarify the following questions when purchasing a RUWI lift table:

- Do I need a fixed top (Basic) or do I prefer extendable or folding tops (Classic, Premium)?

- Is a compact work surface enough for me, or do I often work on large-format workpieces?

- Do I want storage space and drawers directly at the table?

- Do I want to mount my own plate? Then the base frame is ideal.

You can purchase additional clamping accessories and extensions at any time, as all RUWI lift tables are based on the same perforated grid principle. Our team is on hand to answer any questions you may have so that you can find the model that perfectly suits your working environment. And if your requirements grow later, many things can be retrofitted on a modular basis.

With a RUWI lift table, you not only get a mobile workbench, but a real all-rounder for your workshop. Easier processes, back-friendly height adjustment and versatile clamping options: These are the reasons why our lift tables are equally popular in trade, industry and education. If you are still unsure, just get in touch - we will be happy to advise you personally.

FAQs

Many studies clearly show that those who work ergonomically avoid back problems and chronic complaints in the long term. Height-adjustable desks help you to set the perfect working height quickly and easily - to suit your height and the task at hand.

And if the table is also mobile, your workstation comes directly to the workpiece - not the other way around. This saves energy, time and makes your working day noticeably more pleasant.

A scissor lift table is a robust work table designed to lift and lower heavy loads easily and safely. The height is adjusted using a classic scissor mechanism with two crossed legs that are connected via a central swivel joint. On one side, the legs are firmly connected to the frame and work surface; on the other side, they run in plain bearings along the frame. Adjustment is usually hydraulic - either manually by foot pump or electrically, sometimes also via a threaded spindle.

With the RUWI lift table, the stepless height adjustment is carried out conveniently and precisely using a high-quality, German-made hydraulic foot pump.

Our customers particularly like to use lift tables for:

- Assembly and gluing of series parts

- Ergonomic workstations and workbench extensions

- As a mobile and height-adjustable stacking trolley

- In-plant transportation of materials and workpieces

- Flexible extension of the work surface on planing benches

And of course for many other applications - just as you need it for your projects.

In the wood sector, there are different hole diameters for breadboards, for example 19 mm (3/4 inch) or 22 mm. In Germany and Europe, however, hole patterns with a diameter of 20 mm have become the standard. Popular models such as the Festool MFT or the Sauter Variobench also work with this dimension.

The RUWI HPL perforated grid tops have precisely milled 20 mm holes in the standard grid dimension of 96 × 96 mm. This means that our accessories with 20 mm clamping bolts also fit perfectly on other perforated grid tables with 20 mm holes - and vice versa, of course.

Yes, most of the RUWI lift tables arrive pre-assembled. However, so that we can deliver the table safely and in a space-saving manner by a forwarding agent, a few more steps are required before you can get started. Comprehensible assembly instructions are of course included - so assembly is quick and easy.

That sounds like a good idea! We can call you on +49 7402 8414. Otherwise you can also send us an e-mail.

Yes, with pleasure! We work together with various partners who present our lift tables in their exhibition. Alternatively, you can watch our animations and detailed application videos on YouTube. This will give you a good impression.