Versatile milling tools - precisely tailored to your requirements

Purchasing advice for milling tools

With the right range of routing tools, you can get the best out of your router, whether you are a professional or an ambitious DIY enthusiast. Here you will find a comprehensive overview of different types of router bits and useful application tips.

- Rounding cutter

- Flap milling cutter (disk slot milling cutter)

- Chamfer cutter

- Tine cutters (dovetail/ridge cutters)

- Important parameters & application tips

- Conclusion

Rounding cutter

Use and advantages:

Rounding cutters (sometimes also called quarter round or radius cutters) are used to round sharp edges cleanly. Even a small radius (e.g. R2) makes your workpieces easier to grip and reduces the risk of injury. Larger radii, such as R6 or R10, give table tops or handrails a soft, pleasant look and feel.

Typical features:

- Various radii: R2, R4, R6, R8, R10 etc.

- Ball bearing guide for precise guiding along edges

- Shank diameter often 6 mm, 8 mm or 12 mm

- Double-edged carbide for clean cuts

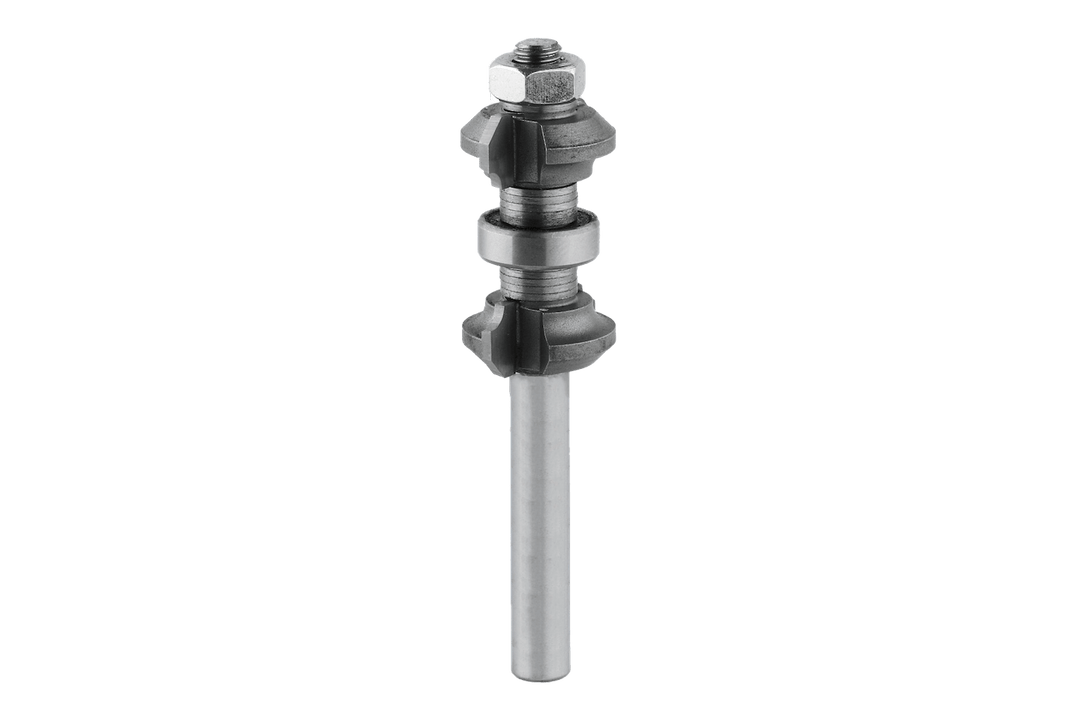

Flap milling cutter (disk slot milling cutter)

Function and main applications:

A lamella cutter (disc groove cutter) mills narrow slots for flat dowels or form springs. Grooves can also be created for back panels or drawer bottoms. Different ball bearings allow you to select the desired depth so that a single cutter can cover several dowel sizes.

Important features:

- Milling disk with 2 carbide cutting edges

- Different thrust rings for depth adjustment

- Mostly 8 mm shank for stability

Advantages compared to the separate flat dowel cutter:

- Only one tool for various dowel sizes and grooves

- Also versatile for plug-in connections or rear panel grooves

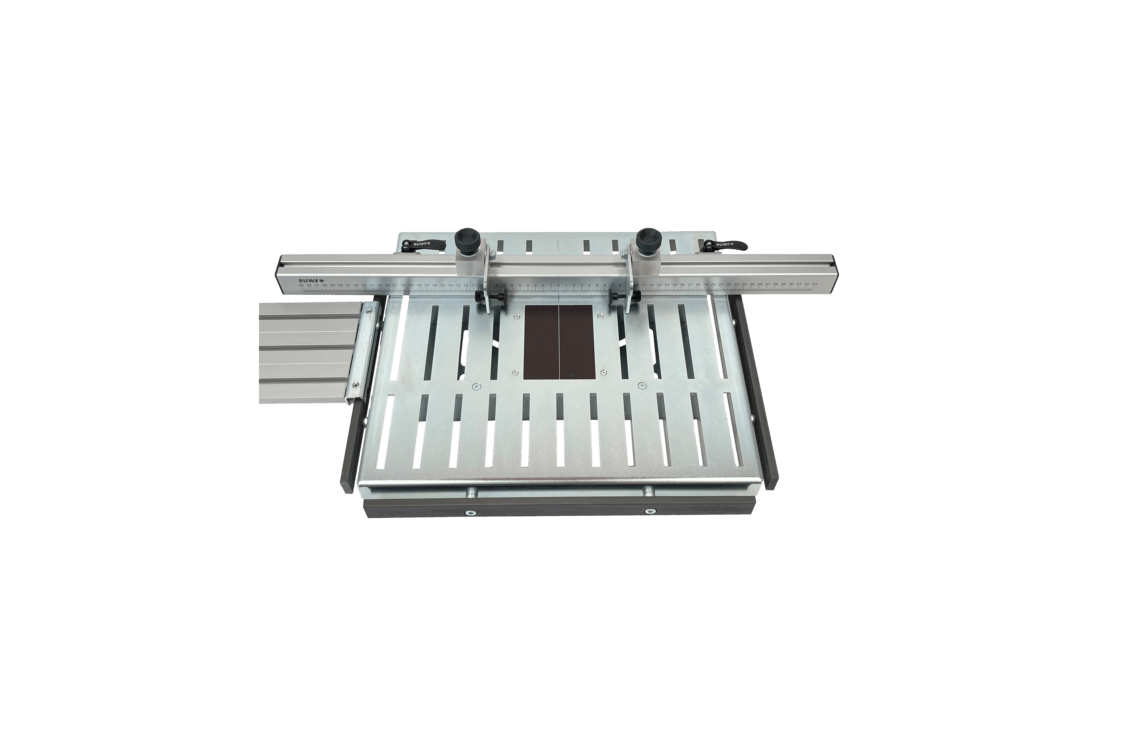

- Precise results in the router table with stop

Chamfer cutter

Why a chamfer?

A chamfer breaks up sharp edges and can be visually or functionally important. Typical angles are 45°, but also 30° or 60° for special designs.

Classic features:

- 45° bevel as standard, other angles on request

- Ball bearing guided or without bearing (in the router table with rip fence)

- Inserts make sense for high fiber volumes

Tine cutters (dovetail/ridge cutters)

Classic wood joints:

Dovetail and burr joints are synonymous with high craftsmanship. With a dovetail router, you can produce these joints very precisely by machine, for example for drawer corners or decorative corner joints. Burr groove cutters work in a similar way, but cut a dovetail groove into which the counterpart is inserted.

Important details:

- Angle e.g. 7°, 10°, 12° or 14°

- Milling diameter & cutting edge length control the size of the joint

- Auxiliary devices or templates for exact fits

Important parameters & application tips

Shank diameter & clamping system:

- 6 mm, 8 mm, 12 mm - choose sufficient stability for larger milling cutters

- Milling cutter two thirds into collet, keep collets clean

Cutting material & geometry:

- Carbide (HM) is standard; inserts are worthwhile for frequent use

- Spiral or diagonal cutting minimizes tear-outs

Speed & feed:

- Larger milling cutter = lower speed

- Several shallow cuts instead of too deep in one pass

- Too slow a feed rate can cause burn marks, too fast leads to chatter marks

Safety & care:

- Hearing protection, extraction and eye protection are mandatory

- Guide the milling cutter against its direction of rotation

- Regularly remove resin and adhesive residue, check ball bearings for free running

Conclusion

Use the full potential of your router with a well thought-out range of routing tools. Rounding cutters ensure pleasant edges, lamella cutters open up freedom for flat dowels, chamfer cutters create elegant corners and tine cutters bring classic wood joints to a modern level.

Ensure solid carbide quality, the right shank diameter and a clean collet. Plan your operations at the right speed, avoid overfeeding and keep your workshop safe. This will help you achieve high-quality milling results and enjoy milling - for every project.