The proven RUWI router table

The solution for wood professionals: Mobile table milling machines from RUWI

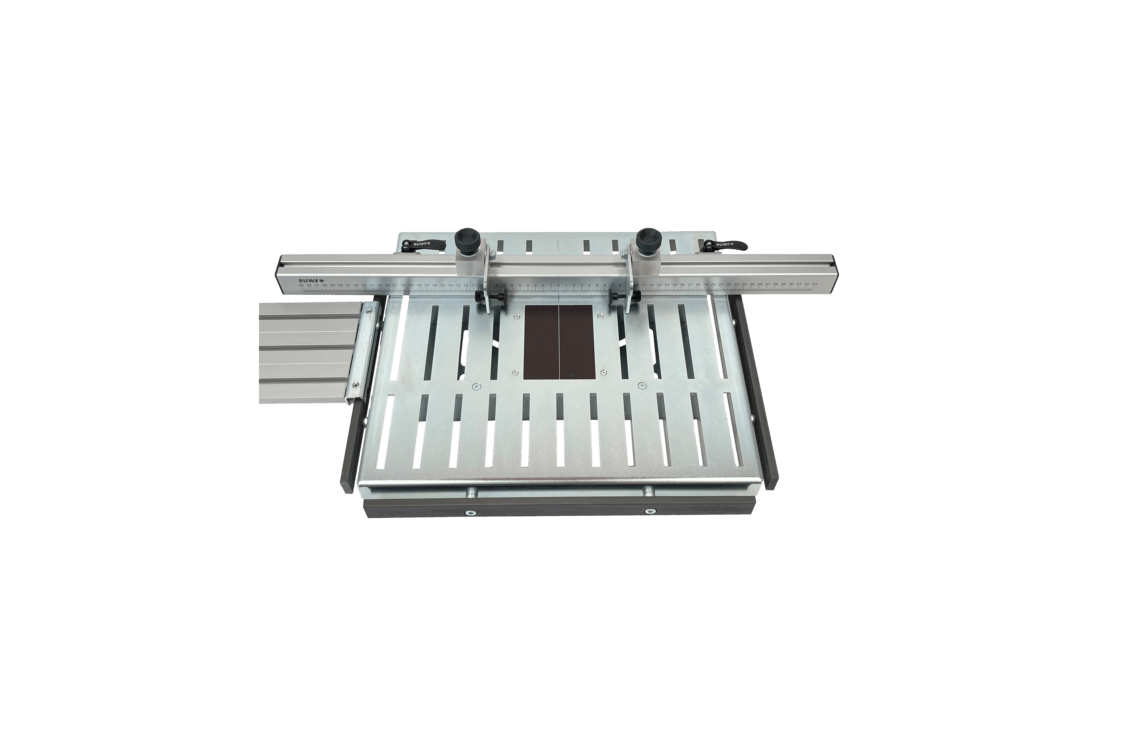

Versatile, flexible, safe: The RUWI router table is a real all-rounder for wood and plastic processing. Chamfering, grooving, rounding, sanding, deburring, flush milling - with the mobile RUWI router table, you work on a stable work table and benefit from a high degree of flexibility at the same time. You can process a wide variety of materials exactly where it suits you best.

We also offer a wide range of accessories for all conceivable applications. Whether as a supplement to an existing table or CNC milling machine or as a versatile stand-alone solution for trade and industry: RUWI table milling machines adapt to every challenge.

- Overview of RUWI milling table models

- RUW router tables in detail

- RUWI milling motor

- RUWI double dust extraction system

- Accessories & upgrades

- Areas of application

- Quality & Made in Germany

- Comparison & buying advice

RUWI router tables: Overview of the four models

RUWI router tables are mobile table milling machines with under-mounted routers that enable professional milling with a high degree of flexibility. They are available in four versions: Basic, Classic, Classic Performance and Premium. They cover a range of one to five-spindle models (expandable up to ten). All variants stand for robust "Made in Germany" quality, sophisticated safety features and modular expandability.

Model and data overview

8,000-25,000 (infinitely variable)

| Model | Table size (mm) | Drive units | Motor power | Speed (rpm) | Milling stroke (mm) |

|---|---|---|---|---|---|

| Basic | 520 × 430 | 1 | 1050 W (standard) | 8,000-25,000 (infinitely variable) | 43 |

| Classic | 640 × 500 | 3 | 1050 W (standard) | 8,000-25,000 (infinitely variable) | 43 |

| Classic Performance | 640 × 500 | 3 | approx. 1600 W (performance) | 3,000-30,000 (infinitely variable) | 55 |

| Premium | 1070 × 500 | 5 (expandable to 10) | 1050 W (standard) | 8,000-25,000 (infinitely variable) | 43 |

The Basic (1-spindle) is a cost-effective and compact way to get started. The Classic (3-spindle) comes with three milling tools on call. The Classic Performance is a special edition with more powerful motors, a higher milling stroke and integrated fine adjustment. The flagship Premium (5-spindle) can even be expanded to up to ten spindles, ideal for complex tasks or continuous industrial use.

RUW router tables in detail

1st RUWI router table Basic (1-spindle)

The RUWI Basic is a cost-effective all-rounder with just one drive unit and a table size of 520 × 430 mm. It is particularly suitable for smaller workpieces or as a mobile addition in confined workshops. Despite its simple design, it can be used for all standard routing tasks - from chamfering and rounding to flush routing. Two integrated transport rollers make it easy to move around the work area.

2. RUWI Classic router table (3-spindle)

The RUWI Classic has three milling motors (1050 W each) and offers maximum efficiency for changing milling tasks on a 640 × 500 mm table surface. It is a proven all-rounder for trade, training and small batch production: Frequently required milling cutters can remain permanently clamped, which minimizes set-up times. Four swivel castors make it fully mobile.

3. RUWI Classic Performance router table (3-spindle, Performance)

The Classic Performance version also has three spindles, but with approx. 1600 W per motor and a speed range of 3,000 to 30,000 rpm. Collets up to 12 mm allow the use of larger milling tools, while a milling stroke of 55 mm creates more clearance for thicker workpieces. The integrated fine adjustment on all spindles ensures maximum precision and repeat accuracy. This makes the Classic Performance the model for users with high demands on performance and accuracy.

4. RUWI Premium router table (5-spindle, expandable)

The RUWI Premium is the flagship with five motors (1050 W each) on a 1070 × 500 mm table. Its expandability to up to ten spindles is outstanding - perfect for complex machining processes without tool changes. Despite its size, the Premium remains mobile (four swivel castors). It is particularly recommended for highly productive companies that frequently work with many different profiles and for industry to make effective use of idle times in production.

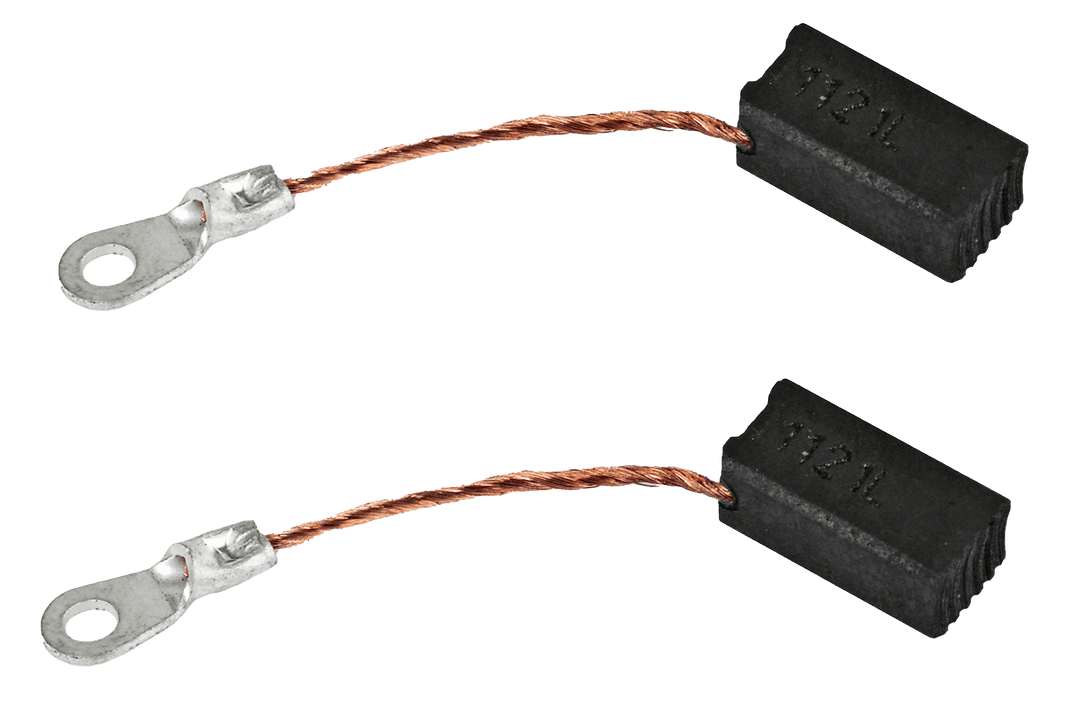

RUWI milling motor - Powerful and durable

Every RUWI router table features a heavy-duty router motor "Made in Germany." Depending on the model (Standard or Performance), power outputs from 1050 W to 1600 W are available, designed for continuous industrial use. The continuously variable speed control (8,000–25,000 rpm or 3,000–30,000 rpm) allows you to process a wide variety of materials at a consistent speed.

Your benefits with the RUWI milling motor

- Flexible speed range: Ideal for milling cutters from small to large.

- Soft start & overload protection: No jerky start-up, constant speed under load.

- Robust design: Backfeed thread protects bearings from dust, double ball bearings for maximum concentricity.

Optimum speed for various applications

- Sanding softwood edges (ø15 mm): approx. 8,000 rpm (avoids burn marks).

- Flush milling multiplex (ø19 mm): 18,000–22,000 rpm.

- Lamello groove in chipboard (ø40 mm): max. 18,000 rpm.

- Rounding / chamfering of plastic edges: approx. 12,000 rpm (prevents smearing).

Technical data

| Rated power | 1050 W (standard) or 1600 W (performance) |

| Operating voltage | 220–230 V / 50 Hz (Schuko connection) |

| Speed | Standard: 8,000-25,000 / Performance: 3,000-30,000 |

| Soft start | Yes, incl. starting current limitation |

| Clamping neck | 43 mm (standard size) |

| Collets | 8 mm (options: 3.175 / 6 / 6.35 / 10 / 12 mm) |

| Return thread | Counter-rotating, protects against dust and dirt |

| Ball bearing | Double ball bearings for maximum concentricity |

RUWI double dust extraction system - clean air for safe working

Efficient dust extraction is essential to minimize harmful wood dust and soiling. RUWI router tables extract dust and chips directly where they are generated - above and below the table top.

Functionality & highlights

- 120 mm extraction nozzle: Compatible with stationary and mobile extraction systems.

- Movable extraction unit: Automatically adjusts to the active milling motor.

- Separators in the lower duct: Prevent secondary air from being drawn in.

- Automatic switch-on (optional): Starts the extraction system automatically with the router.

Advantages of the RUWI double extraction system

- Health protection: Reduces wood dust and protects against respiratory diseases.

- Cleanliness: Less dust on workpieces, machines and workshop floor.

- Tool protection: Minimizes the effects of dust on the motor, bearings and electronics.

- DGUV-tested: Meets high safety standards for commercial use.

Technical data at a glance

| Suction connection | Ø 120 mm (standard) |

| Air output (approx.) | 170–230 m³/h at 20 m/s |

| Negative pressure (20 m/s) | < 1000 Pa (hohe Absaugleistung) |

This not only makes your work safer, but also much more pleasant - chips and dust are effectively removed, visibility remains clear and the work results are of a higher quality.

Accessories & upgrades - modular and retrofittable

A major advantage of RUWI router tables is their modular design: You can retrofit additional accessories and add-on parts as your application needs grow. With the exception of the fine adjustment module (ex works or retrofittable on newer models), everything can also be integrated at a later date.

Fine adjustment module

This allows you to adjust the cutter height in 0.1 mm increments. This fine adjustment is standard on all three Classic Performance engines. It can also be retrofitted to Basic, Classic, and Premium models (from model year 2024).

Additional drive units

The Premium in particular is predestined for this: You can add up to five additional milling motors to use a total of ten spindles in parallel. However, Classic and Basic can also be expanded to a limited extent. Mounting points and Schuko sockets are already prepared so that an upgrade is easy to carry out.

Table extensions

Table extensions are available as accessories for larger workpieces or more storage space. You can attach them to the side or front of your RUWI router table without tools. Even bulky parts can be processed in a more stable way - the system still remains mobile.

Stop and guide systems

Stop ruler: For straight-line routing work (chamfers, grooves, rounding). With Classic and Premium with fine depth adjustment.

Arc ruler: Enables stepless routing of inner and outer radii. Perfect for shaping work or profiling.

3D unit: Processing of multi-curved parts thanks to two movable workpiece supports and an adjustable tool cover. Ideal for complex shapes.

Quick-release system & other accessories

RUWI offers special quick-action clamps, clamping bolts, and clamps for quickly securing workpieces. Various collets (6 / 6.35 / 8 / 10 / 12 mm) and hardened union nuts ensure secure holding of the cutters. A plastic insert ring can reduce the gap around the cutter, ensuring greater safety and perfect machining of small workpieces.

Areas of application: Who benefits from the RUWI router table?

The multi-spindle concept, mobility and robust design make the RUWI milling table extremely versatile. Here are some areas in which it proves particularly effective:

Craft businesses (carpentry, joinery, interior fittings)

- Small series and one-off production: Chamfering, rounding, grooving, copy milling

- Efficient processes without constant retooling

- Small space requirement, simply roll away when not in use

- Ideal as a supplement to a stationary table milling machine or CNC

Industrial companies (furniture construction, series production)

- Parallel operation alongside CNC systems for finishing and further processing

- Robust continuous-running motors for shift operation

- Easy to relocate when converting production lines

Educational institutions (vocational schools, training centers)

- Learn several milling processes on one machine (chamfer, groove, rounding, etc.)

- Logical structure, simple and safe operation

- GS- and DGUV-approved, ideal for training workshops

Motorhome and caravan construction, model making, plastics processing

- Material mix: wood, plastics (e.g. Plexiglas®, Makrolon®, GRP), aluminum

- Deburring, profiling, grooving, sanding - all in one place

- Mobile and flexible for assembly work

Advantages of buying a mobile bench router from RUWI

- Quality & safety: Solid construction, DGUV-tested, durable components.

- Easy handling: low-maintenance technology, intuitive operation.

- Variety of applications: For wood, plastics, aluminum, composite materials.

- Time saving: Preset milling tools, less set-up time, hardly any trial milling.

- Innovation & modularity: The only supplier of mobile, multi-spindle table milling machines in Germany. Made in Germany.

Quality "Made in Germany" & safety

RUWI stands for reliable mechanical engineering quality from Dornhan (Baden-Württemberg). Regional production and a high level of vertical integration enable strict quality controls. Every milling table is tested before delivery and meets all EU standards (CE, GS, BG/DGUV tests).

- Robust construction: Frame and table constructions made of steel or torsion-resistant aluminum profiles.

- High-quality motors: Industrial-grade drives with soft start, PTC protection and low vibration.

- Safe operation: protective hoods, tool covers, insertion rings, double extraction.

- Regionality: responsibility for the region, supplier parts from local partners.

Comparison with other milling table solutions & purchasing advice

Compared to conventional router tables, RUWI scores above all with its multi-spindle concept - several routers are ready for use at the same time, which drastically reduces set-up times. The mobility (castors) and compact design are also unique selling points. Although classic stationary spindle moulders have an advantage with large milling heads, they require more space and complex set-up processes. RUWI combines the best of both worlds and is therefore ideal for frequently changing milling tasks and smaller batch sizes.

FAQs

Commercially available tools up to max. 40 mm diameter for the speed range from 8,000 to 24,000 revolutions. The RUWI drive motors are fitted with an 8 mm diameter collet chuck as standard. Optional sizes are 3.175 / 6 / 6.35 / 8 / 9.5 and 10 mm.

Chips and dust are extracted to the rear through extraction channels above and below the table surface. On the RUWI router table Classic and Premium, these can be moved to minimize the loss of suction power. The RUWI router table / router table is connected to a ø120 mm suction hose at the rear suction connection.

Yes, the RUWI router table can be connected to a standard household socket (usually with around 230 volts) without any problems.

Yes, the assembly and installation of the milling table is easy and can be done by yourself.

That sounds like a good idea! We can call you on +49 7402 8414. Otherwise you can also send us an e-mail.

We have various trade partners who have our tools on display. We also attend various trade fairs such as HOLZ-HANDWERK and LIGNA. You are welcome to contact us and we will send you a recommendation in your area.

We are also happy to go into more detail or look at specific work processes. Our team consists of various wood professionals such as master carpenters who have a broad view and a lot of experience.

Strong. You are welcome to get in touch with us and then we can look at a solution. For example, some customers send us a part in the post and we record a video.