RUWI safety system for sliding table saws

Process workpieces of all kinds on your sliding table saw more safely and efficiently than ever before.

Maximum security and precision in 10 secondsPressing – turning – fixing: With the RUWI system, you can process workpieces of any shape and size safely and precisely. Das werkzeuglose Spannen in nur 10 Sekunden ermöglicht es, alle denkbaren Werkstücke mit geringer Unfallgefahr und Zeitverlust zu bearbeiten.

Product overview

The RUWI safety system offers you a safe and precise solution for your sliding table saw. It is available in Premium and Classic variants and is compatible with most popular machines. The swing clamp enables you to use it flexibly, for example on machines from Altendorf, Martin and Felder.

But which variant is right for you? Both systems are perfectly suited for safely sawing small workpieces or for difficult cuts. However, if you also want to clamp long workpieces directly on the sliding carriage, we recommend the premium version. In addition to the Classic equipment, this also contains two Multiplex auxiliary stops with retaining tips and a second swing clamp for clamping the workpiece.

| Characteristics | Safety system sliding table saw Classic | Safety system sliding table saw Premium |

| Safe sawing of small workpieces | ✔ | ✔ |

| Feed stop | ✔ | ✔ |

| Angled auxiliary stop | ✔ | ✔ |

| Auxiliary stop narrow | 2 pieces | |

| Swing clamp | 1 piece | 2 pieces |

| Manufacturer | Martin, Altendorf, Felder and other manufacturers on request | Martin, Altendorf, Felder and other manufacturers on request |

| Buy the classic sliding table saw safety system | Buy the Premium sliding table saw safety system |

“ The idea for the security system came about in my own workshop. As a carpenter, I often lacked the right tools to work on small workpieces without endangering my hands. “

Reiner Ruggaber , developer of the sawing system

In the hectic everyday life of a joinery, there is often little time for occupational safety measures because it is supposed to be faster without them. With the RUWI safety system, the safe variant is achieved convincingly quickly and without any significant expenditure of time. Thanks to the fact that it can be used in seconds and is easy to use, you are always protected in the best possible way and can concentrate fully on your work.

The safety system is an effective work protection device for all common sliding table saws. The swing clamp enables the saw system to be used for machines from Altendorf, Martin and Felder and others. Various auxiliary stops can be placed or fixed quickly, safely and easily to match the workpieces.

areas of application

- Carpentry/Joinery

- wood industry

- Furniture construction

- Professional DIY/Woodworker

- training workshops

- facilities for people with disabilities

Compatible machines

- Altendorf

- Martin

- Fields X-Roll

- Format 4 fields

- fields hammer

- Panhans

- SCM

- wood power/mini max

- As well as other format circular saws with format carriage/sliding table. Contact us! We would be happy to advise you on whether your sliding table saw is compatible.

How to use the RUWI security system

The RUWI safety system is delivered fully assembled and can be mounted and adjusted on all standard sliding table saws without tools. To do this, insert the clamping cylinder with the sliding block into the groove, turn it 90 degrees and clamp it tight. The feed stop has a long slot nut that is matched to the slot width of the respective machine.

Trimming solid wood

When trimming boards or planks, clamp a clamping cylinder in the front area on the sliding carriage and attach the swivel arm to fix the board. At the rear, press the feed stop against the face of the board to hold it in the desired position.

With the premium set, you can fix the workpiece at the front and back with a clamping cylinder and swivel arm. Also mount the two narrow auxiliary stops between the clamping cylinder and the sliding carriage. The retaining tips of the auxiliary stops provide additional security against unintentional shifting of the workpiece.

Safe sawing of small parts

Holding small workpieces close to the saw blade is a thing of the past.

When sawing small parts, place the auxiliary fence on the sliding carriage and set the angle and the distance to the saw blade. The auxiliary stop is then firmly connected to the sliding carriage with the help of the swivel arm. Then insert the feed stop into the groove and adjust the angle and the distance to the saw blade. Then fix the stop with the clamping lever.

Master difficult cuts – exact bevels and angles

The RUWI safety system for the sliding table saw offers various functions that enable problematic cuts to be made safely and precisely. Workpieces can be positioned at different angles and distances from the saw blade thanks to the flexible feed fence and the auxiliary fence at an angle. The large adjustment options of the clamping cylinder and the pressure plate enable workpieces of all sizes to be clamped securely and securely.

In addition, the system is ideal for cutting exact bevels and angles, as it enables precise workpiece guidance and fixation. Due to the tool-free and quick assembly, stops and auxiliary devices can be flexibly and easily adjusted. In this way, carpenters can implement specific cutting angles with great precision and safety.

Clamping long workpieces directly on the sliding carriage (Premium)

With the premium version of the safety system, carpenters can clamp and saw long workpieces safely and precisely. The additional equipment with a swing clamp and the narrow auxiliary stop enables flexible fixing of longer workpieces. The boards can be rotated and clamped as you like to achieve a perfect cut.

Components of the security system

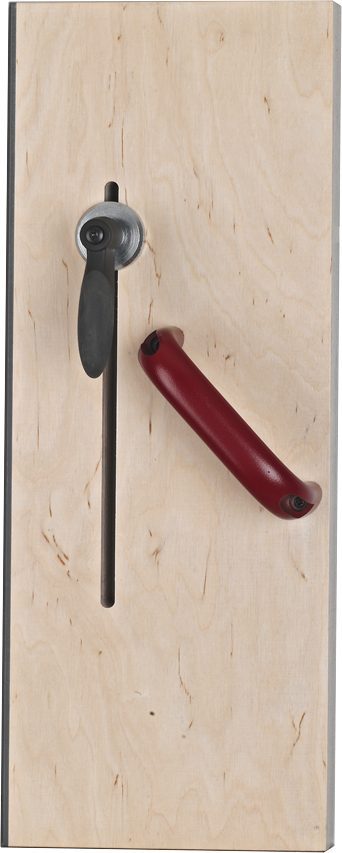

Spannzylinder

The clamping cylinder enables tool-free attachment at any point in the groove of the sliding carriage. The large adjustment range of the clamping cylinder allows flexible mounting directly on the sliding carriage or an inclined clamping of the auxiliary stop as well as clamping other devices in between.

In combination with the swivel arm, components can be easily and securely fixed on the sliding carriage without having to hold them by hand. Work efficiently and safely with the RUWI system.

Zuführanschlag

The feed fence allows a workpiece to be securely clamped against the auxiliary fence without your fingers being in the danger zone of the saw.

It consists of a handle and a sliding block and is inserted from above into the groove of the sliding carriage. When fixed in the desired position, it allows linear movement. Distance and angle to the saw blade can be precisely adjusted using the clamping lever.

Druckteller

Thanks to the ball joint and rubber pad, the pressure plate adapts flexibly to the shape and size of the respective workpiece. This means that even uneven workpieces can be processed safely. The pressure plate is pressed against the workpiece in order to fix it securely and enable precise machining. The ball joint allows the pressure plate to be turned in any desired direction.

The rubber pad ensures that the workpiece is gently fixed without damaging it.

Schwenkarm

The swivel arm of the RUWI safety system consists of a handle with a spindle and the pressure plate.

The swivel arm can be slipped over the clamping cylinder where it can be rotated 360 degrees for positioning.

The rubber-coated pressure piece is placed on the workpiece and clamped with the ergonomic turning handle. In this way, components for sawing can be clamped onto the sliding carriage without having to hold them by hand.

Wandpaneel

The wall panel is a practical solution for storage in the workshop. The bracket made of powder-coated metal is simply mounted on the wall next to the sliding table saw. The individual components of the RUWI system can be attached to the various hooks and brackets so that they are always ready to hand and clearly arranged.

With the wall panel, you always have everything you need for your work on the sliding table saw at hand and save unnecessary searching and clearing work.

Hilfsanschlag schräg

The auxiliary stop is used to securely fix components on the sliding carriage of the sliding table saw. It is mounted on the sliding carriage using a clamping cylinder and can be flexibly adjusted. The big advantage is that the angle and distance to the saw blade can be individually adjusted through the slot. A rubber edge along the long side provides additional grip to keep the workpieces securely in place.

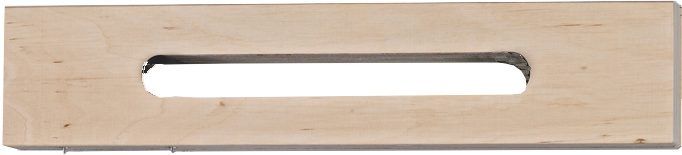

Hilfsanschlag schmal (Premium)

safety notice

The two narrow auxiliary stops included in the Premium Set can be used for trimming or separating long workpieces. They can be fixed flexibly and without tools on the sliding carriage with the clamping cylinders. With the screwed-in retaining tips, they also ensure that the workpieces remain securely in the desired position when sawing.

In our online shop you can buy our products directly from the manufacturer. Due to regional production and manufacturing, we have all items in stock and can deliver quickly. Here you can find out more about RUWI the company .

FAQ

Other RUWI products in the wood processing sector