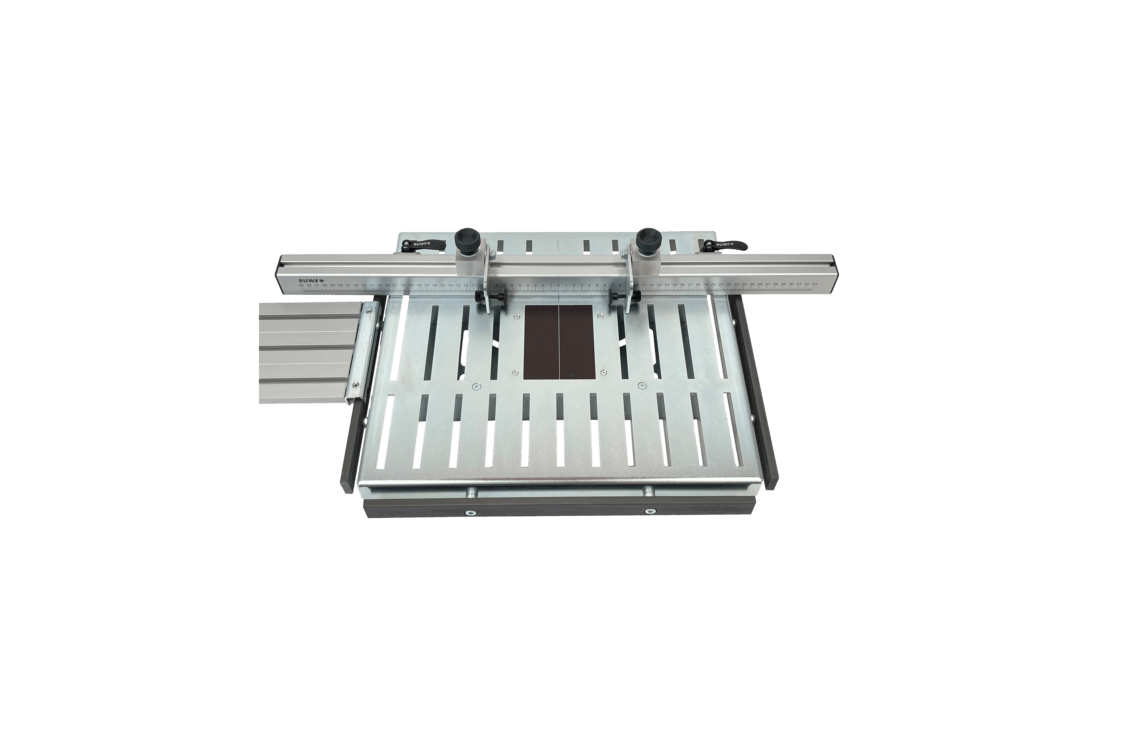

RUWI router table drive motor 1050 Watt

RUWI10700

- Quality craftsmanship made in Germany

- Fast and reliable shipping

- From wood professionals for wood professionals

- In stock - in your workshop in 3-5 working days

- Reordered - back soon

Our tools are shipped by DPD and DHL and usually arrive within 3-5 days. You will receive shipment tracking by e-mail.

Our larger tools are shipped by Schenker and arrive within a few working days. On request, the shipping company can also come at a desired time and you can coordinate with the shipping company by telephone.

Packaging dimensions

- Packaging: In cardboard box, shipped by DHL or DPD

- Weight: 3.5 kg

Scope of delivery

- 1 x motor with safety plug

Our tools and machines are built for long-term use. We only use high-quality components and have gained a lot of experience to avoid problems in the workshop. That's why we have no problems with warranty requests - even if it goes beyond 2 years. We are always looking for a good solution together.

We have 100% spare parts in stock.