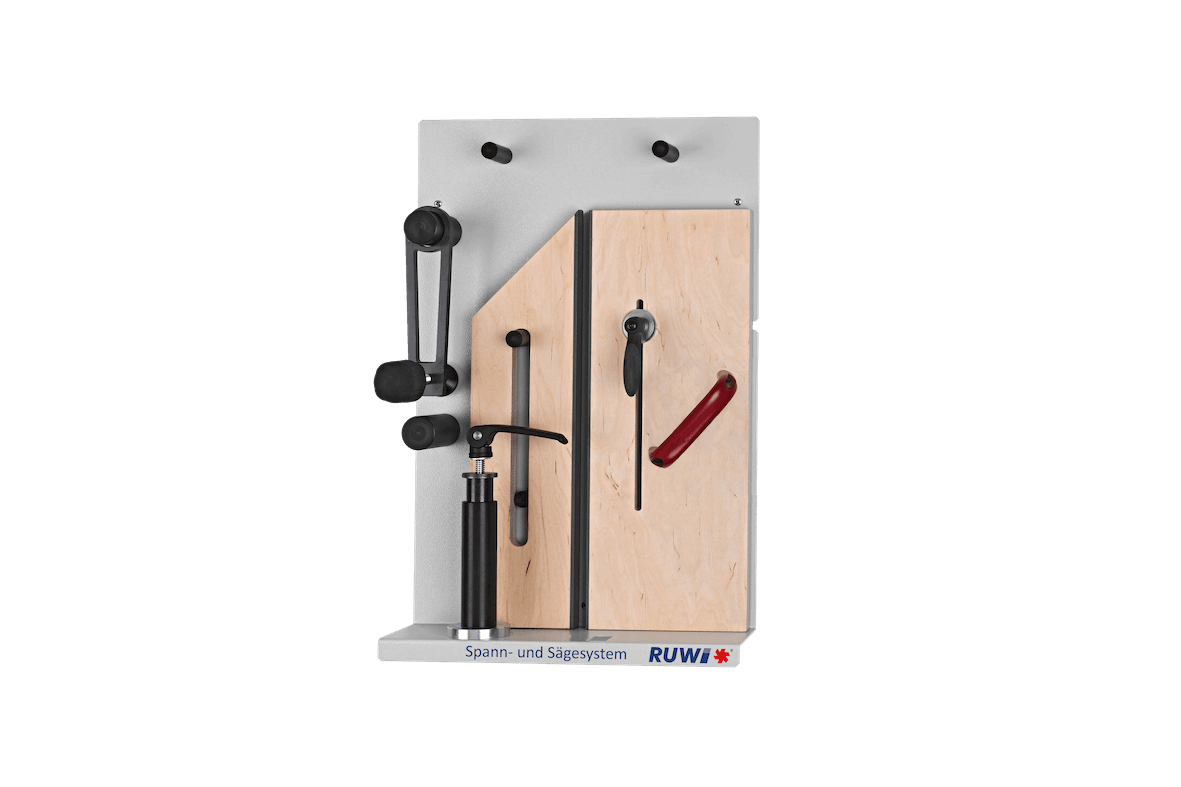

Robust welding tables and clever clamping technology

Welding table with perforated plate or groove

Fixing, clamping, clamping, welding, assembling - all this is possible on our high-quality welding tables. When you order a welding table from us, you not only benefit from top quality direct from the manufacturer, but also from decades of expertise from our family business. This expertise can be found in every centimeter of our products and is reflected in our service.

Which welding table should you buy?

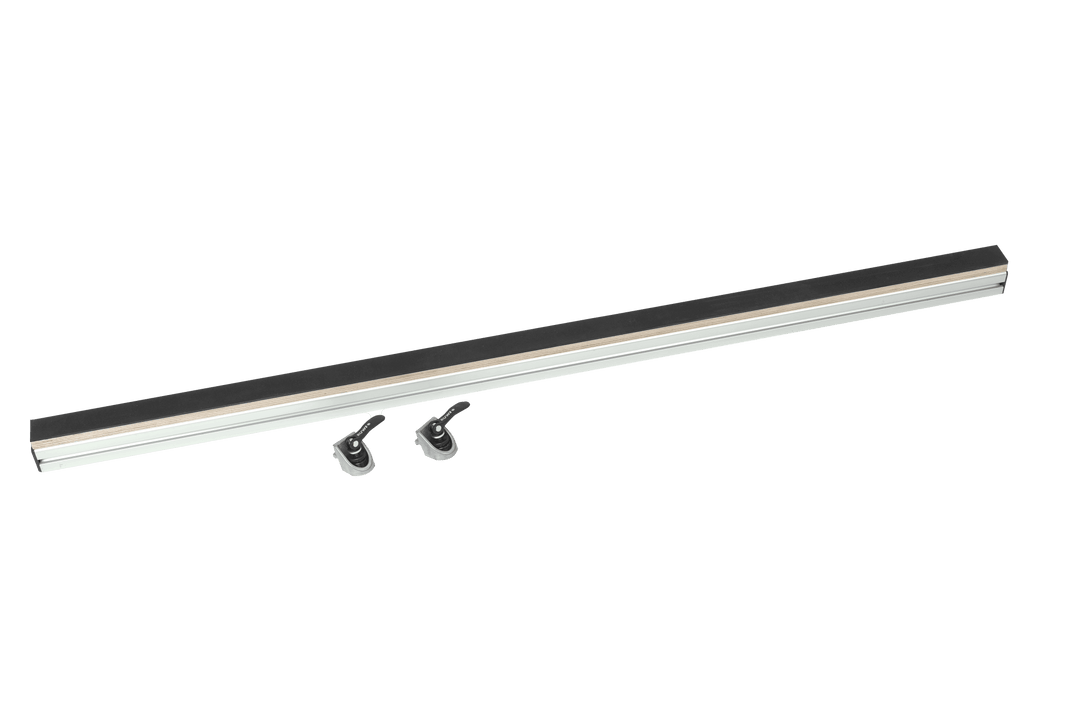

Before buying, it is important to decide what work you want to do with it and in what context. Is it certain that the workplace will always remain in the same place? Then a static welding table may be worthwhile. If you need more flexibility, one of our lifting tables with a hydraulic foot pump may be the better choice. The worktop is also crucial: do you need a grooved or perforated grid? In our online store, you can also find sets that include matching support rails in addition to the table.

Tip: Thanks to our accessories, rails, and robust material, RUWI welding tables are also suitable as clamping and workbenches, e.g., for assembly work or welding preparation.

What should you look out for when buying a welding table?

The following points will help you make your choice:

Working height

Height adjustability is essential for ergonomic working. RUWI offers hydraulic welding tables (using a foot pump) that can be continuously adjusted from 46 to 106 cm. The base frame is designed as a lifting or scissor lift table - giving you maximum flexibility and mobility. Leg tables with an articulated base can be adjusted from 86 to 93 cm.

Load capacity

Depending on your application, you need the right load capacity. RUWI leg tables support up to 500 kg, and lift tables up to 300 kg. Consider how heavy your workpieces typically are to ensure a safe work environment.

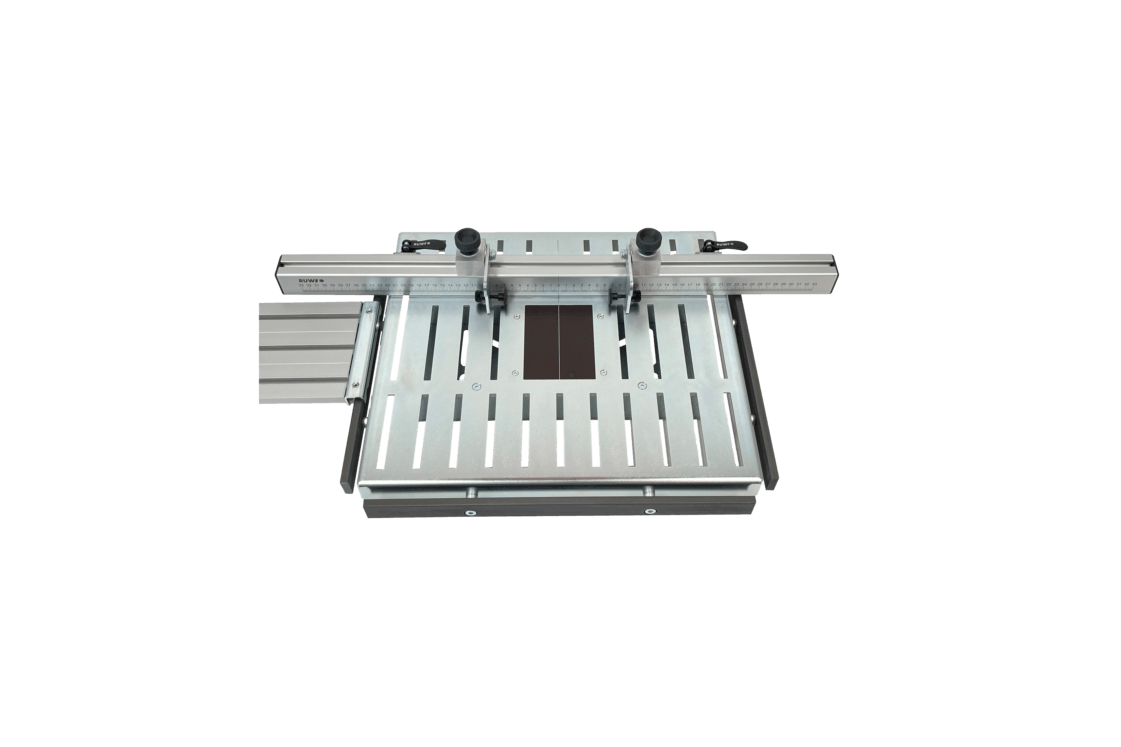

Groove or hole pattern

You can get leg tables and welding lift tables from us with either a groove or hole pattern.

- Hole grid: Fix workpieces using screw clamps or screws.

- Clamping system groove (10 mm wide): Use clamping claws for fixing.

Which variant makes sense for you depends on your workpieces and fastening methods.

Work surface

All our welding tables have a 1.2×0.8 m work surface - ideal for smaller, more precise welding work. For larger projects, you can place several leg tables next to each other and align them using the adjustable feet.

Material

Our work surfaces are made of 4 mm steel with a phosphated finish. This is robust enough to withstand welding heat and spatter, plus it provides rust protection and good adhesion for the welding material.

Tip: The welding lift table is also perfect as an addition to existing, larger welding tables. If a workpiece protrudes, simply move the mobile RUWI table to the right place, lock the castors and pump it to the right height using the foot pedal.

Advantages of buying a RUWI welding table

If you opt for a RUWI welding table, you are choosing a configurable workstation that adapts to your needs. Our hydraulic welding tables in particular are flexible and easy to operate. They impress with:

Stability

The 4 mm thick grooved or perforated plates made of phosphated steel can support 300 to 500 kg, depending on the model.

Flexibility

Our modular accessories can be attached without tools using a clamping system - fast, secure and versatile.

Ergonomics

The height adjustability and mobility of our welding and assembly tables enable a healthy posture and an ideal working environment.

Thanks to precise fixing via a hole grid or groove system, most work and produce faster, saving time and money. RUWI not only stands for a first-class range of static and mobile welding tables, but also for great customer service.

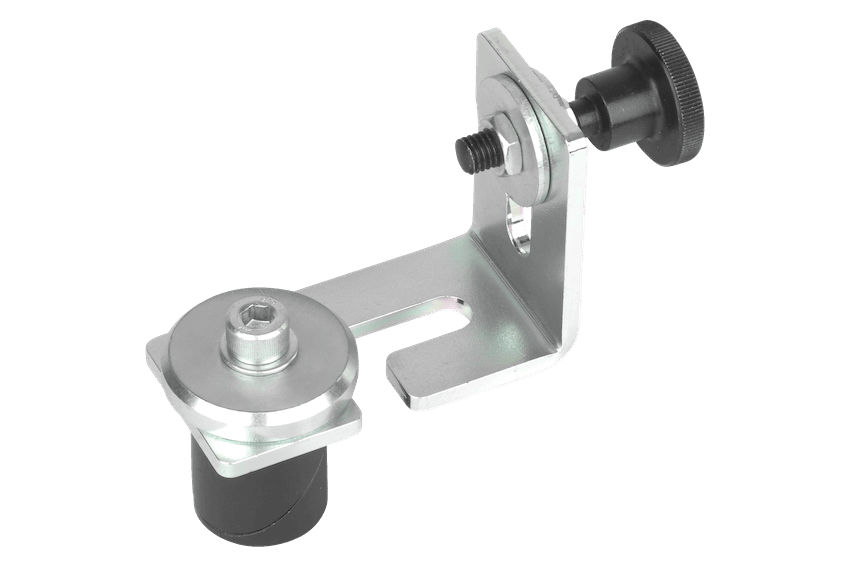

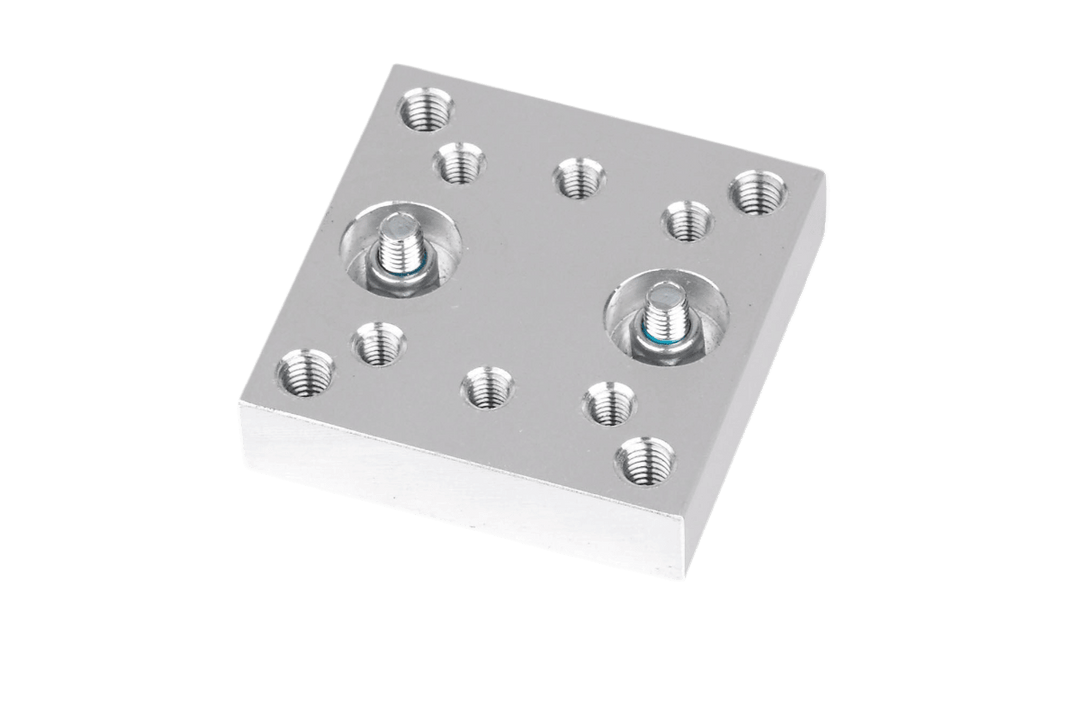

Eccentric clamps and clamping bolts

Secure fixing for workpieces

Eccentric clamp sets including clamping bolts (Ø 16 mm / Ø 28 mm + washer) are ideal for quickly securing workpieces. Vertical and horizontal clamps with clamping bolts in various sizes ensure reliable clamping, while the TW16 200/100 screw clamp (with adapter disc and clamping bolt Ø 16 or Ø 28 mm) is suitable for spot fixing.

The clamping bolt 16 K with clamping lever (Ø 16 mm) or the clamping bolt 16 S with screw (Ø 16 mm) offer a clamping range of 0-36 mm. For larger workpieces, you can use the clamping bolt 28 K (Ø 28 mm) with clamping lever or the clamping bolt 28 S (Ø 28 mm) with screw, which provide more clamping force.

Stainless steel top plate and perforated grid

FAQs

That sounds like a good idea! We can call you on +49 7402 8414. Otherwise you can also send us an e-mail.

We have various trade partners who have our tools on display. We also attend various trade fairs such as HOLZ-HANDWERK and LIGNA. You are welcome to contact us and we will send you a recommendation in your area.