Face milling

Definition and explanation of face milling in woodworking

Face milling is a technique that allows you to mill a wooden workpiece to a desired thickness. Precise angles and even surfaces are essential for beautiful, high-quality wood products. Raw wood from the sawmill is not directly suitable for decorative purposes; it is first dried and processed. Surface milling helps you to create a smooth and even surface.

In this article, you will find out how face milling differs from other techniques, which materials you can process with it and what other options a router offers you.

Table of contents

- Definition of

-

Technical basics of face milling

- Machine

- Tool

- Milling device

- Work surface

- Which face milling cutters are used for face milling?

- What materials are used for face milling?

-

Fields of application for face milling machines

- Creating a flat surface

- Face milling of unevenness and protrusions

- Pockets, recesses and cut-outs in surfaces

- Milling protruding edges flat

- Face milling of tree slices or end grain cutting boards

Definition: What is face milling?

When face milling, you remove a wavy surface from a solid workpiece so that it is as smooth and even as possible. It is a secondary process that follows on directly from sawing. Professional wood processors usually use planing machines (jointers and thicknessers) to "plane" pieces of wood quickly and efficiently. However, their width is limited and they only process rectangular cross-sections. Although a planer is slower, it is more versatile - it can process solid wood parts or wood-based materials of almost any size, which is particularly interesting for tree slices or epoxy resin-filled wood panels.

Technical basics of face milling

A typical face milling machine consists of the following elements:

- Router

- Suitable interchangeable tool (face milling cutter)

- Work table with clamping devices

- Milling device with XY guide and plunge mechanism

From simple hobby solutions (dismountable milling carriage + hand router) to CNC-controlled professional devices, everything is available on the market. The router itself allows you to clamp various router bits (e.g. insert router bits). Thanks to the XY guide, you can guide the machine in two axes and lock it in the desired positions.

Machine

A handheld router with a compatible guide system is essential. Make sure it has the right shank size (8, 10, 12 mm) and an adjustable speed range – excessively high speeds can cause burn marks in soft wood or quickly dull the tool.

Tool

In the router, you use cutters with the largest possible cutting width for face milling (typically 30 mm diameter). Indexable cutters are advantageous because you can rotate or replace the insert when it wears out. End mills with fixed cutting edges are also possible, but you should opt for low-wear carbide cutters.

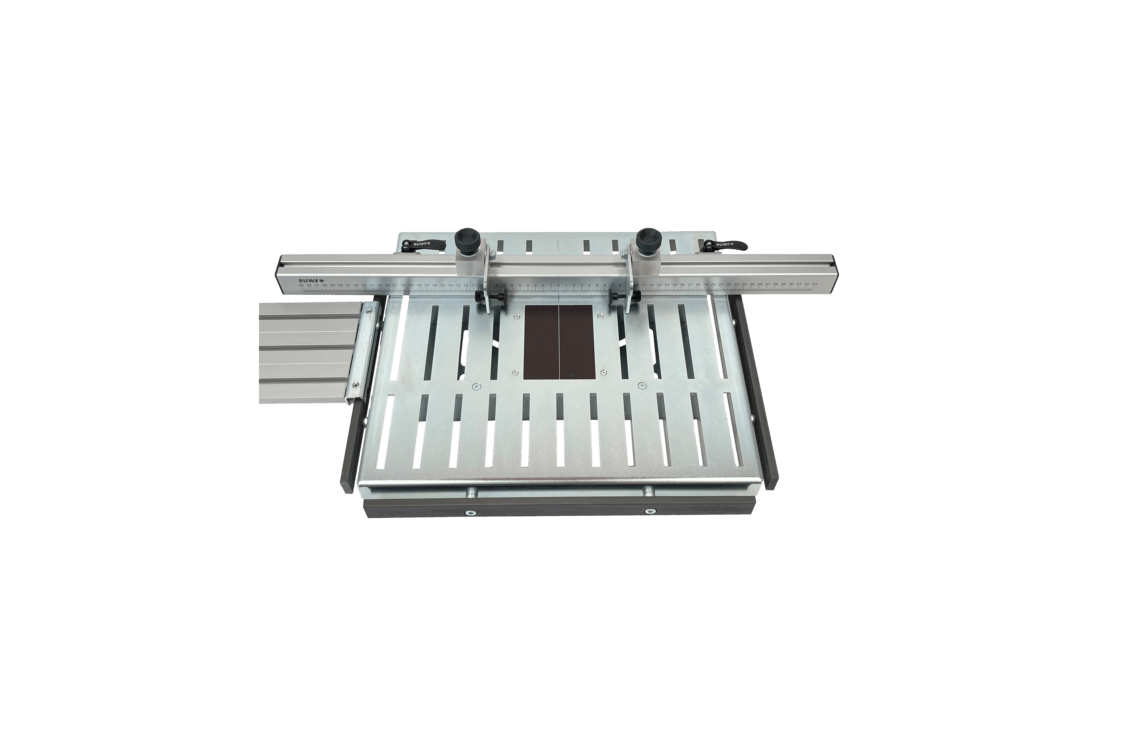

Milling device

It consists of rails (XY guide) on which a carriage with a plunge mechanism for the router runs. This allows you to move the machine in both axes in a controlled manner or lock one axis, e.g. to "format" a workpiece. Higher-quality systems are precisely manufactured, can be dismantled and stowed away to save space.

Work surface

A stable, level workbench forms the basis so that your workpiece rests securely. A sufficiently large perforated plate with suitable clamping technology is a good choice. Professional tables are often height-adjustable and equipped with plenty of accessories (clamps, stops, etc.).

Tip: The RUWI router table (a mobile table milling machine) combines the advantages of a stable work table with the flexibility of a router.

Which face milling cutters are used for face milling?

In most cases, face milling cutters with an 8 mm shank and a diameter of around 30 mm are sufficient. Two or three cutting edges are common. Popular brands include Titmann and ENT. It's important that the cutter is robust enough to withstand the high stresses of face milling.

What materials are used for face milling?

Surface milling is primarily used to level out uneven surfaces, especially with solid wood. Wood-based materials such as chipboard, glulam or plywood are usually already relatively smooth, so sanding is often sufficient. Nevertheless, you can also process material mixes (wood and acrylic/epoxy resin) with face milling cutters. Just make sure that there are no metallic inclusions that could damage your milling cutter.

Fields of application for face milling machines

You can use a face milling machine in many scenarios:

- Producing a flat surface: Preparing boards, beams and blocks of solid wood into semi-finished products.

- Plan milling of unevenness and overhangs: After gluing, for example, mill uneven joints smooth.

- Pockets, recesses and cut-outs: Rows of holes, holders for glass plates or lamps can be milled into the surface.

- Routing protruding edges: Precisely format workpieces or add profiles.

- Face milling of tree slices or end grain cutting boards: End grain is difficult to plane, but can be smoothed well with a router.

You may also be interested in these milling processes:

If you would like to find out about other milling processes in woodworking, take a look at our encyclopaedia for information on CNC milling, profile milling, groove milling and more.