Milling table extraction – the intelligent double extraction from RUWI

The double dust extraction for better work at the RUWI milling table

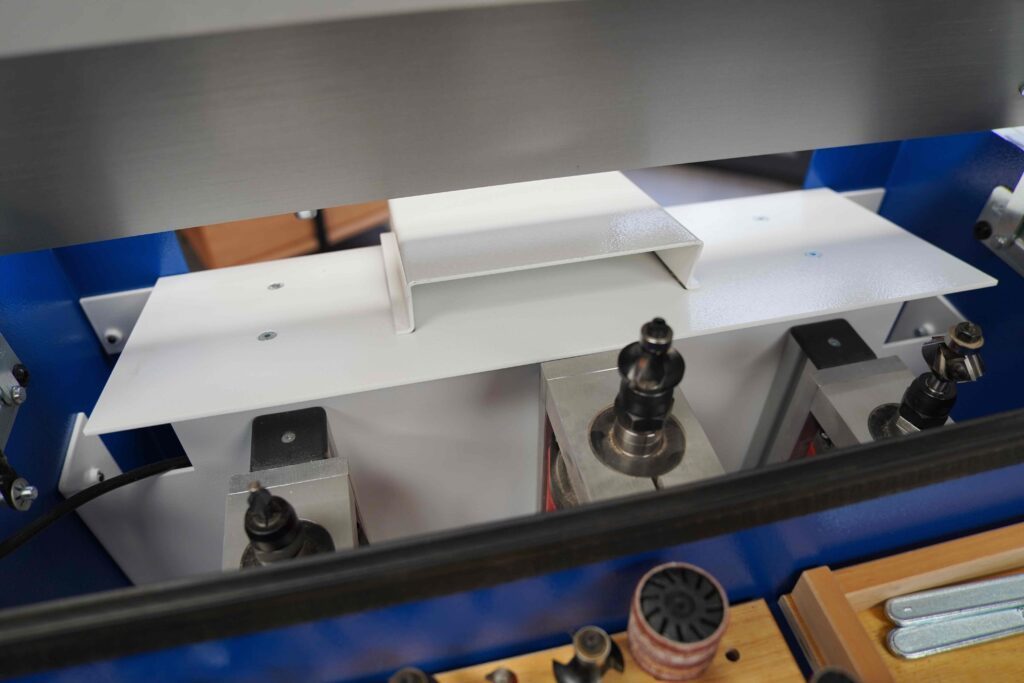

Effective router table extraction of wood dust is essential to reduce the risk of dust inhalation and associated respiratory diseases during woodworking and to improve workplace air quality. With the RUWI milling table, any chips and dust that occur are not only extracted from above, but also from under the milling table.

The milling table double suction simply explained

The suction connection included as standard with the RUWI milling machine has a diameter of 120 mm and can be easily connected to a suction hose. The suction unit is then simply pushed to the desired milling unit and the upper and lower suction channel are automatically in the correct position. Separators in the lower suction channel minimize that “wrong air” is drawn. For optimal use, the suction should be installed in such a way that it starts automatically when the machine is switched on. During the milling process, extraction takes place both above and below the milling table, thus minimizing dust exposure.

Unique selling point

Double suction

The milling table double extraction with the lower and upper extraction channel ensures that any chips are extracted right where they are created.

Suction connection 120mm

The milling machine has a 120 mm suction connection and is therefore compatible with common suction systems.

DGUV wood dust tested

The RUWI milling table has been tested for wood dust by the German statutory accident insurance and thus meets the highest safety standards.

“ As a carpenter, I know how important cleanliness and health protection are. That is why we have installed a double extraction system on all milling tables. “

Reiner Ruggaber , developer of the milling table

Advantages of the RUWI milling table double extraction

In the hectic everyday life of a joinery, there is often little time for occupational safety measures because it is supposed to be faster without them. With the RUWI safety system, the safe variant is achieved convincingly quickly and without any significant expenditure of time. Thanks to the fact that it can be used in seconds and is easy to use, you are always protected in the best possible way and can concentrate fully on your work.

Technical details of the RUWI milling table extraction

| Overview | Technical detail | advantage / function |

|---|---|---|

| Diameter suction connection | 120mm | Common hose diameters of stationary and mobile suction devices |

| Movable suction | Both suction channels are always pushed to the drive unit that is currently being worked on | This minimizes that the suction draws “wrong air”. In addition, the dust is always extracted directly where it is generated |

| Negative pressure at 20 m/s air speed | < 1000 Pa at the machine frame | Negative pressure shows how much air is being sucked out of an area. The higher the negative pressure, the more air is extracted, which increases the performance of the extraction. |

| Air consumption at an air speed of 20 m/s | 170 – 230 m³/h | The air consumption of an extraction system in m³/h indicates how much air volume the extraction system can absorb and transport per hour. A higher air volume rate increases the performance and effectiveness of the extraction system. |

Structure of the RUWI milling table double extraction

All RUWI milling tables have a round suction socket on the rear side to which a suction hose with a diameter of 120 mm can be connected. Then the upper suction channel is inserted. In Classic and Performance machines with several motors, the entire suction unit can be moved and is always pushed onto the drive unit that is currently being used. The lower suction channel is then also automatically moved to the correct position.

The extraction is often synchronized with the milling machine via an automatic switch-on so that it starts automatically when the on/off switch is pressed. When processing workpieces, the resulting chips and dust particles are now effectively extracted above and below the cover plate.

Compared to conventional milling table extraction

| Overview | Conventional milling table extraction | RUWI milling table suction |

|---|---|---|

| Diameter connection piece | Often only the possibility to connect the hose (ø35 or ø50mm) of a vacuum cleaner / dust extractor | Maximum compatibility and performance with the ability to connect 120mm diameter tubing |

| Double suction under and on the milling table | With conventional milling tables, suction is usually only from below. The motor or large parts of it are often enclosed in a housing and are therefore always in contact with dust and chips. | With the RUWI milling table, the lower suction is directly under the milling spindle, which minimizes the impact of dirt on the motor. A return thread in the spindle also ensures that even the finest particles cannot penetrate to the bearings |

| Use in the commercial sector | Conventional or self-made milling tables and milling devices are often not suitable or approved for commercial use due to a lack of or insufficient extraction. | With the RUWI milling table, the lower suction is directly under the milling spindle, which minimizes the impact of dirt on the motor. A return thread in the spindle also ensures that even the finest particles cannot penetrate to the bearings |

In our online shop you can buy our products directly from the manufacturer. Due to regional production and manufacturing, we have all items in stock and can deliver quickly. Here you can find out more about RUWI the company .